3.1 超疏水表面在霜层初始生长阶段的抑霜性能

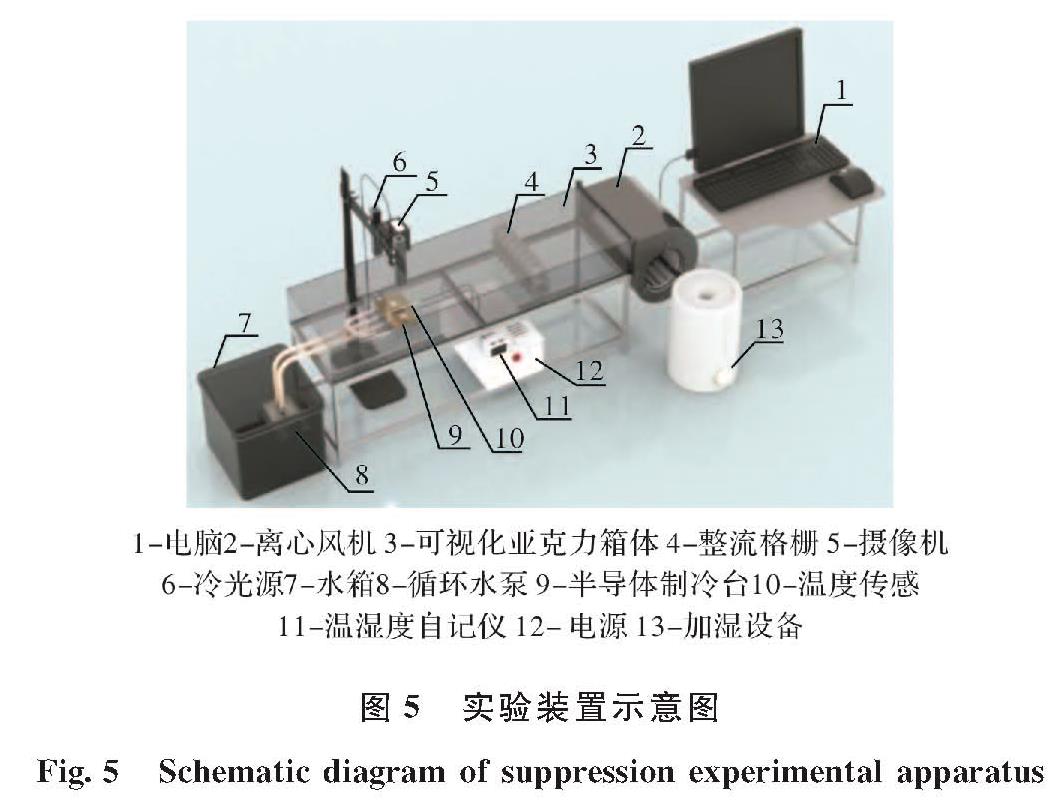

为探究霜层初始生长阶段不同湿润性表面霜层覆盖率随时间的变化情况,利用上述实验平台创造一个低温高湿的实验环境对两种湿润性铝基平片表面展开对比实验.翅片大小均为2 cm×2 cm,环境温度5 ℃,为模拟低温下的结霜现象,使空气中的水蒸气在冷表面上直接生成针状霜层,调节冷表面温度为-13 ℃.测得实验台内相对湿度86%,送风风速1.3 m/s,实验得到两种表面霜层覆盖率随时间的变化情况如图6.

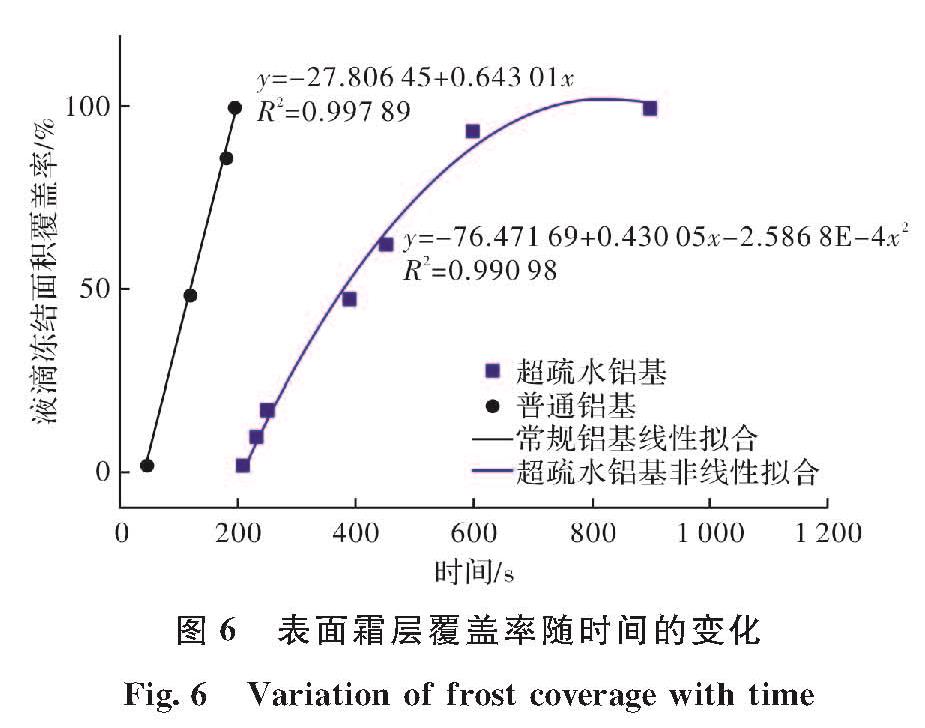

图6 表面霜层覆盖率随时间的变化

Fig.6 Variation of frost coverage with time

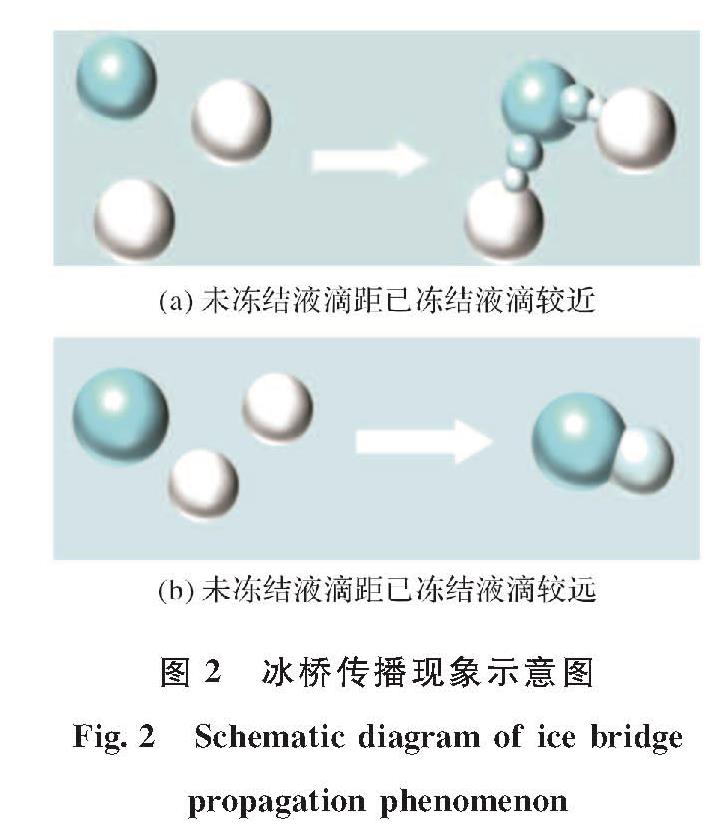

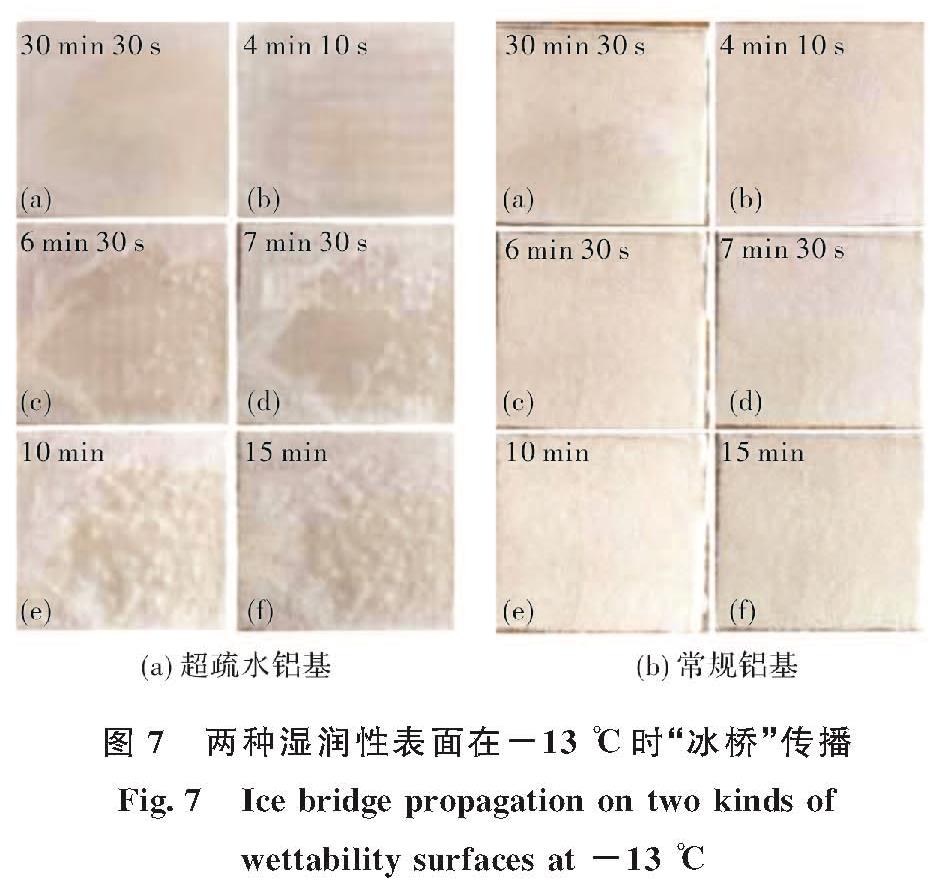

由图6可知,常规铝基表面45 s开始结霜,至250 s时,表面霜层均匀分布.而超疏水铝基表面210 s开始结霜,900 s时表面液滴完全冻结.说明常规铝基表面液滴冻结发生时间明显早于超疏水铝基.此外,结霜过程中超疏水铝基在任意时刻表面霜层覆盖率增速均明显小于常规铝基.由图7可知,常规铝基表面霜层的密度及厚度基本一致,而超疏水铝基表面霜层生长稀疏、不均匀,且表面出现“冰桥”现象.表明常规铝基表面传热效率基本一致,“冰桥”传播现象不明显.

图7 两种湿润性表面在-13 ℃时“冰桥”传播

Fig.7 Ice bridge propagation on two kinds of wettability surfaces at -13 ℃

3.2 超疏水表面在强制对流结霜过程的抑霜性能

将不同润湿性铝基翅片竖直放置在实验台中,翅片间距为1 mm.室外环境温度7 ℃.考虑到此实验中制冷板为多个翅片提供冷量,为使各个翅片上形成均匀针状霜层,调节冷表面温度为-18 ℃.测得翅片前后两侧室内温度均为6.85 ℃,翅片迎风侧、背风侧相对湿度分别为90%、77%,翅片迎风侧、背风侧风速分别为0.6 m/s、0.73 m/s、实验观测每5分钟直至结霜60 min的两翅片表面霜层重量、厚度及密度的变化情况.

(1)两种翅片霜层重量对比分析

每五分钟测量霜层重量汇总并进行线性拟合如图8所示.

图8 霜层重量随时间的变化

Fig.8 variation of frost weight with time

由图8可知,开始结霜5 min时,两翅片表面均已生成霜晶.超疏水及常规铝基翅片结霜量分别为0.658 8 g、0.721 8 g.结霜25 min时,霜层处于“霜层完全发展期”,两种表面各处均出现霜层.超疏水铝基翅片及常规铝基翅片结霜量分别为1.746 g、2.382 4 g.超疏水铝基结霜量仅是常规铝基翅片的73.29%,可见超疏水表面在结霜初期抑霜效果优异.结霜进行至50 min时,超疏水霜层结霜量仍为常规铝基的71.36%.经线性拟合,常规铝基霜层重量平均增速为0.084 81 g/min,超疏水铝基霜层重量平均增速为0.055 29 g/min,较常规铝基减缓了34.81%.说明在整个结霜过程中常规铝基霜层的生长速率均较超疏水铝基快.

(2)两种翅片霜层厚度对比分析

按迎风、背风方向将翅片分为前部、中部、尾部三部分.实验发现,三部分霜层厚度增长均经历“飞速”—“缓慢”的过程,且以中间部分变化最大,尾部背风侧变化最小.这是因为随着霜层厚度不断生长,霜层密度不断增加,翅片冷表面与室外空气间形成一层“隔热层”,影响了后续的传热效率.当霜层进入“完全发展期”后,传热效率趋于稳定,霜层生长缓慢.两润湿性铝基翅片三部分的厚度随时间的变化情况如图9所示.

图9 翅片前部、中部、尾部霜层厚度随时间的变化

Fig.9 Variation of frost layer thickness at the front, middle and tail of fins with time

由图9可知,在整个强制对流结霜过程中,超疏水铝基翅片表面及常规铝基翅片表面霜层最厚处均在迎风侧.结霜60 min时,超疏水铝基翅片及常规铝基翅片前部霜层厚度分别为1.531 mm及1.799 mm,超疏水铝基翅片霜层厚度为常规翅片的85.10%.同时,翅片中部霜层厚度分别为1.203 mm及1.662 mm,相比常规翅片减少了27.62%.尾部霜层厚度为1.370 mm及1.747 mm,相比常规翅片减少了21.58%.说明超疏水铝基表面的霜层厚度随时间增长的速率在任意位置均比常规铝基表面慢,整体表现出优良抑霜特性.

(3)翅片霜层密度增大成因分析

实验发现,随着结霜的进行翅片表面霜层密度逐渐增大,且结霜前期霜层密度生长速度迅猛,结霜后期,霜层密度增速减缓,但仍可见霜层越来越密实.如图 10所示,在霜层的各个表面上均能明显看到有细小透明霜晶出现,说明此时此霜晶正在发生“回融-冻结”过程.

图 10 翅片表面霜层晶体融化示意图

Fig.10 Schematic diagram of frost melting on fin surface

研究发现,当霜层增长至一定高度后,由于边缘霜层远离冷表面致使表面温度升高.当表面温度增至0 ℃以后,霜晶开始相变融化,融化后的冰晶水沿重力方向向下渗透,抑制了霜层高度的生长.并且向下渗透的冰晶水进入霜层内部后再次冷凝使得内部霜层越来越密实,霜层变密导致传热系数增加.边缘霜层温度下降,霜层得以继续增高,这也就是霜晶的回融-倒伏现象.

3.3 超疏水表面的融霜性能

结霜1 h后关闭制冷系统和送风系统,使两种湿润性翅片霜层在室外环境中(温度7 ℃、相对湿度37%、风速1.0 m/s)融化.观测翅片表面霜层融化形态并记录表面霜层完全融化所需时间.融霜结束后测量干海绵吸取的化霜水重量,实验结果如图 11所示.

图 11 翅片霜层重量、融化后化霜水停留位置及化霜时间对比图

Fig.11 Comparison of the weight of the frost surface on the fins, the location of the defrosting water and the time of defrosting

实验发现,化霜完毕后常规铝基翅片底部聚集一大片厚度为1.5~4.2 mm的液膜,竖直翅片表面也存在较大尺寸的液滴粘附.而超疏水铝基翅片底部基本无液滴残留,且其竖直翅片上的残留液滴尺寸小、数量少.同时,这一实验结果验证了前述液滴在超疏水表面频繁发生弹跳-合并-滚动-滑落现象导致表面液滴覆盖率小这一超疏水表面抑霜机理.

由图 11可知,常规铝基翅片掉落化霜水重1.267 g,残留在表面的化霜水重4.137 g; 而超疏水铝基翅片掉落化霜水重2.691 g,残留在表面的化霜水重1.083 g.常规铝基翅片上残留化霜水的比例为76.56%,而超疏水翅片上残留化霜水比例为28.70%,相比常规翅片减少了47.86%.此外,常规铝基翅片霜层全部融化需要25 min,而超疏水铝基翅片需要16 min,仅是常规铝基翅片的64%.说明超疏水技术的应用对减小化霜时间和抑制二次结霜起到了良好的改善作用.

,得到临界半径rc与相应临界自由能ΔGC的表达式为

,得到临界半径rc与相应临界自由能ΔGC的表达式为