基金项目:国家自然科学基金资助项目(51678474)

第一作者:李正发(1988—),男,硕士,工程师,从事输变电工程设计研究.E-mail:304550629@qq.com. 通信作者:王先铁(1979—),男,博士,教授,从事钢结构与钢管混凝土结构研究.E-mail:wangxiantie@163.com

(1.国网甘肃省电力公司建设分公司,甘肃 兰州 730050; 2.西安建筑科技大学 土木工程学院,陕西 西安 710055)

高强材料; 中空夹层钢管混凝土构件; 薄壁; 大空心率; 弯扭性能

(1.State Grid Gansu Power Construction Company, Lanzhou 730050, China; 2.School of Civil Engineering, Xi'an Univ. of Arch.& Tech., Xi'an 710055, China)

high strength material; concrete-filled double skin steel tubular members; thin-walled; large hollow ratio; bending and torsional performance

DOI: 10.15986/j.1006-7930.2022.04.010

中空夹层钢管混凝土构件(Concrete-Filled Double Skin Steel Tubular,简称CFDST)是由同心放置的内、外钢管与夹层混凝土组成的一种组合构件.这类构件相比于钢管混凝土构件,截面更为开展,在复杂工况下承载力高且自重较轻.近年来,CFDST构件在输电杆塔、高架桥桥墩、风力发电机塔筒及海洋平台柱等工程中得到广泛应用[1-2].为了减轻构件自重,实现预制装配,并适应结构的受力特征,可采用高强钢与高强混凝土组成的大空心率、大径厚比的锥形中空夹层钢管混凝土构件.

国内外学者对CFDST构件的力学性能开展了一系列研究.尧国皇等[3]对CFDST构件进行了有限元分析,分析中考虑钢管初应力的影响,推荐了构件抗弯刚度计算公式.史艳莉等[4]对8个大空心率的方套圆CFDST构件进行横向撞击试验,研究构件的撞击受力性能; Chen等[5]对7个十二边形CFDST构件进行纯弯试验研究和有限元分析; 周绪红等[6]研究了不同截面形式和空心率的CFDST柱在往复扭转下的滞回性能; 罗伟等[7]运用有限元软件ABAQUS建立了CFDST结构塔筒在纯扭往复荷载作用下的有限元模型,提出了该类构件的抗扭承载力简化计算方法.以往对锥形中空夹层钢管混凝土构件的研究相对较少,且多集中于构件轴压与偏压力学性能的研究.Han等[8]通过试验研究了锥度对中空夹层钢管混凝土构件轴压承载性能的影响; Ghasem等[9]对锥形CFDST构件进行抗震性能研究,外钢管截面形状为矩形,内钢管截面形状分别为方形、菱形和圆形; 韩祎等[10]采用有限元软件ABAQUS分析了圆锥形CFDST构件的压弯剪受力性能,得到了构件的破坏状态与受力机理.上述研究多集中于普通强度钢管和普通强度混凝土组成的CDFST构件,且研究参数大多数在规范限值以内,尚未开展采用高强材料且空心率和径厚比超限的锥形中空夹层钢管混凝土构件的弯扭性能研究.

对采用Q690钢材和C120混凝土的锥形中空夹层薄壁钢管混凝土构件(Tapered High Strength Thin-Walled Concrete-Filled Double Skin Steel Tubular构件,简称THSTW-CFDST构件)开展弯扭性能研究,分析该类构件的弯扭性能、破坏形态和受力机理,并研究不同参数对构件弯扭性能的影响.

锥形高强中空夹层薄壁钢管混凝土构件的示意图如图1所示,试件的主要参数为内钢管径厚比(Di/ti)、外钢管径厚比(Do/to)、空心率(χ=Di/(Do-2to))以及内外钢管是否设置纵向加劲肋.其中:Di、ti分别为内钢管直径和壁厚; Do、to分别为外钢管直径和壁厚.

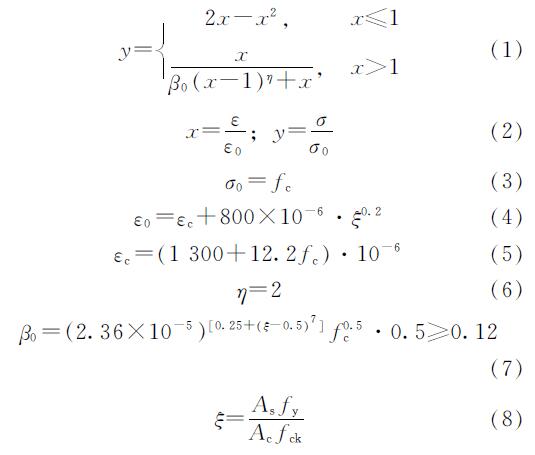

采用有限元软件ABAQUS对THSTW-CFDST弯扭构件进行单向荷载作用下的数值模拟分析.Q690钢材选用双折线模型,弹性模量取206 GPa,屈服强度取690 MPa,泊松比取0.3.混凝土立方体抗压强度取120 MPa,弹性模量Ec取4.49×104 MPa,泊松比取0.20.混凝土采用ABAQUS中的塑性损伤模型,其塑性参数取值如表1所示,选用的混凝土应力-应变模型计算公式如下[11].

式中:Ac为夹层混凝土的横截面面积; As为钢管的横截面面积; fck为混凝土的轴心抗压强度标准值; fy为钢材屈服强度; fc为混凝土的圆柱体抗压强度.

内、外钢管采用4节点完全积分的壳单元(S4),其余部分采用8节点减缩积分实体单元(C3D8R).对模型进行划分时,尽量使混凝土、内钢管、外钢管和加劲肋的节点网格重合.内外钢管、加劲肋和混凝土之间为面-面接触,界面接触模型由法线方向的接触和切向的粘结滑移组成.法向方向的接触采用“硬”接触模拟,切向方向采用库伦摩擦模型,钢与混凝土接触摩擦系数取0.6[11],钢与钢接触摩擦系数取0.3[12],加劲肋分别与内外钢管绑定,端板与内外钢管绑定.

THSTW-CFDST弯扭构件有限元模拟边界条件如图2所示.

其中,底部端板完全固定,约束所有方向的平动和转动,以模拟构件底部固接.上端板与加载梁绑定,模拟试验加载情况,采用位移加载,实现构件弯扭受力.

基于上述建模方法,采用有限元软件ABAQUS,建立THSTW-CFDST构件的弯扭受力模型,构件的基本参数如表3所示.根据构件在实际不同工况下的受力状态,结合文献[14]中弯扭试验选取的弯扭比,确定弯扭比取值.

各构件破坏形态如图5所示,其中,WN-1A-0.98中WN-1A为构件编号,0.98为构件的弯扭比.由图可知,弯扭比对构件的破坏形态影响较大.当弯扭比较小(0.98)时,构件发生明显扭转,受压区明显鼓曲,鼓曲呈45°螺旋状,且钢管表面出现明显的45°应力分布带(图5(a)); 受拉区外钢管底部与下端板连接处开裂(图5(b)),且在扭矩作用下,开裂处向加载端环向延伸,为弯扭组合破坏.当弯扭比为1.48时,构件破坏形态类似于弯扭比较小的情况,但由于弯矩作用的增大,在受压侧外钢管下部出现应力集中,没有明显的45°应力分布带,且鼓曲更为水平(图5(c)),斜率低于小弯扭比的情况; 受拉侧的断裂与小弯扭比一致(图5(d)),同样出现45°的拉力带,但并不明显,同样为弯扭组合破坏.当弯扭比较大(2.95)时,构件破坏形态类似于受弯构件,在构件底部受压区出现明显鼓曲(图5(e)),部分构件出现螺旋状鼓曲,同时由于剪应力的影响,角部混凝土处于三向受压的复杂受力状态,呈现出斜压柱的传力特点.

保持构件底面尺寸不变,对同等条件下无锥度的中空夹层钢管混凝土弯扭构件进行有限元分析.图6为两类构件的扭矩-转角关系曲线对比.由图可知,二者的扭矩-转角曲线趋势基本一致,无锥度构件的刚度略大于THSTW-CFDST构件,二者的抗扭承载力差别不大,但变截面构件的受力更合理.

通过对THSTW-CFDST构件在弯扭荷载作用时各部件的应力发展过程进行分析,可知构件的受力分为三个阶段,如图6所示.

图6 弯扭构件扭矩-转角关系典型曲线

Fig.6 Typical torsion-rotation angle relationship curve of the bending and torsional member

(1)弹性阶段(OA段)

A点为外钢管截面纤维最大应变为10 000×10-6时对应的扭矩[15].在此阶段,随着转角的不断增大,扭矩呈线性增长.在弯矩和扭矩共同作用下,受压区外钢管与混凝土之间几乎没有相互作用,内钢管与混凝土之间的相互作用力很小,钢管和混凝土均单向受压,双向受剪; 而受拉区外钢管和内钢管的横向变形被夹层混凝土限制,产生环向拉应力.接近A点时,外钢管开始屈服,并逐渐向内发展,随即外钢管受压区、加载端上部和内钢管受拉区达到屈服.

(2)弹塑性阶段(AB段)

随着荷载继续增大,扭矩与转角呈非线性关系.在弯矩和扭矩共同作用下,外钢管受拉区屈服后,逐渐向内发展,随即外钢管受压区、加劲肋、内钢管受拉区和受压区先后屈服,受压区混凝土承受的纵向应力和剪应力继续增加,受压区外钢管与夹层混凝土接触,相互作用逐渐增大,钢管与混凝土均处于复杂受力状态.随着荷载增加,外钢管受压区出现鼓曲,弯扭比较小构件的内钢管出现内凹屈曲.B点为THSTW-CFDST构件进入塑性阶段的起点.

(3)塑性强化阶段(BC段)

钢管大面积屈服后,夹层混凝土虽然已经出现了裂缝,但由于内外钢管的约束,仍不会发生破碎,且有效抑制了外钢管的内凹屈曲,从而使构件的抗扭承载力继续增大,构件表现出良好的塑性.C点时构件发生破坏.

不同弯扭比下,THSTW-CFDST构件的破坏形态不同,为全面了解弯扭比对其受力性能的影响,选取空心率和径厚比均超限的WN-1构件为研究对象,分别在弯扭比m为0.25、0.33、0.4、0.5、0.67、0.84、1、1.11、1.25、1.47、1.67、2、3、4、5、6、8和10时对构件进行非线性有限元分析,得到的扭矩-转角关系曲线图7所示.按文献[3]确定不同弯扭比时构件的抗扭屈服承载力Tu,取构件WN-1纯扭状态下的抗扭承载力为Tmax,绘制Tu/Tmax关系曲线,如图8所示.

图7 不同弯扭比时WN-1构件扭矩-转角曲线

Fig.7 Torsion-rotation angle curves of WN-1 member for various ratios of bending to torsion

图8 Tu/Tmax-m关系曲线

Fig.8 Tu/Tmax-m relationship curve

由图可知,当弯扭比m≤0.3时,随着弯扭比增大,后期抗扭承载力减小,构件小头发生破坏.当弯扭比0.3<m≤0.84时,构件具有良好的延性,屈服后承载力有小幅提高; 弯扭比对抗扭承载力的影响较小,随着弯扭比的增大,弯扭构件抗扭承载力有一定程度提高.这是因为构件具有锥度,在纯扭状态下,构件顶部发生破坏,当构件承受小于0.84弯扭比的荷载时,构件主要发生扭矩为主的弯扭破坏,其外钢管屈服首先发生在顶端,随即向下、向内延伸,主拉应变大于主压应变,弯矩的作用会削弱,最终构件小头发生破坏.当弯扭比0.84<m≤6时,曲线走势较为平缓,但后期承载力下降,这是由于构件发生弯曲为主的弯扭破坏,后期构件底部鼓曲,承载力下降,仍具有一定延性,构件在大头处发生破坏.在此弯扭比区间,弯扭比对构件抗扭承载力的影响较大.当弯扭比m>6时,抗扭承载力的变化幅值开始减小,构件后期延性降低,当外钢管开始鼓曲时,拉应变较大,曲线没有明显屈服平台,构件承载力下降,最终在大头处发生破坏.

综上所述,当弯扭比m≤0.3时,构件发生扭转破坏; 当0.3<m≤0.84时,构件发生以扭转为主的弯扭破坏; 当0.84<m≤6时,构件发生以弯曲为主的弯扭破坏; 当m>6时,构件发生弯曲破坏.当m≤0.84时,破坏截面为构件小头; 当m>0.84时,破坏截面为构件大头.

为明确不同参数对THSTW-CFDST弯扭构件受力性能的影响规律,建立不同参数的足尺分析模型.参考110 kV钢管输电杆的截面尺寸,确定基本模型的几何尺寸,构件长度为8 000 mm,外钢管大/小头尺寸为Ø1 200/1 040×12,内钢管大/小头尺寸为Ø970/810×11.钢管均采用Q690钢材,混凝土强度等级为C120.为延缓薄壁钢管屈曲,增加了给内、外钢管配置纵向加劲肋的对比组.

弯扭比取m=1,空心率的变化范围为0.62~0.92,构件的外钢管直径和壁厚相同.在改变空心率的同时,内钢管径厚比基本保持一致.THSTW-CFDST构件的扭矩-转角曲线如图9所示.随着空心率增大,构件的极限承载力和刚度均增大.当空心率由0.62增大到0.92时,无肋构件的抗扭承载力提高43.52%,带肋构件的抗扭承载力提高40.41%,带肋构件抗扭承载力较无肋构件高2.73%~5.01%.这是由于空心率增大是通过改变内钢管直径实现,内钢管直径增大,夹层混凝土厚度减小.考虑到在空心率达到0.86时,通过增大空心率的方法来提升构件抗扭承载力的效率较低,并且过大的空心率会给构件带来局部稳定问题,因此建议构件的空心率不宜大于0.86.

不同空心率时,外钢管与夹层混凝土之间的相互作用力在极限状态下沿高度变化曲线如图 10所示,其中P和N分别为外钢管与夹层混凝土在受压区和受拉区的相互作用力,负号为受压区.随着空心率增大,无肋构件和带肋构件中外钢管和夹层混凝土之间的相互作用均减小,无肋构件的变化幅度大于带肋构件.由于加劲肋的设置,带肋构件相互作用力沿高度从上到下逐渐减小,斜率大于无肋构件,这是由于加劲肋提高了构件的整体性.上端板扭转带动外钢管转动,无肋构件在加载后期上部钢管变形较大,与混凝土产生挤压,相互作用力增大.无肋构件与带肋构件底部相互作用力突然增大,其原因为弯矩在底部最大,弯扭耦合作用下,构件底部发生应力集中,混凝土被压碎.

锥度的取值范围为0.29~1.43,通过改变小头截面尺寸改变构件锥度.THSTW-CFDST构件在弯扭比为1时的扭矩-转角曲线如图 11所示.随着锥度增大,构件的极限承载力和刚度均减小,构件极限扭转角也减小.当锥度由0.29增大到1.43时,无肋构件的抗扭承载力降低95.71%,带肋构件的抗扭承载力降低92.71%,带肋构件抗扭承载力比无肋构件大2.54%~4.87%,这是由于锥度变化导致构件破坏截面发生变化.当θ≥0.43时,构件在弯扭比为1时的破坏截面为构件小头处; 当θ<0.43时,构件在弯扭比为1时的破坏截面为构件大头处.建议构件锥度不宜超过0.72.

不同锥度时,外钢管与夹层混凝土之间的相互作用力在极限状态下沿高度变化曲线如图 12所示,其中,P和N分别为外钢管与夹层混凝土在受压区和受拉区的相互作用力,负号为受压区.当锥度较小(θ=0.29)时,构件相互作用力沿高度大小基本一致,随着锥度增大,构件底部相互作用力减小,顶部相互作用力增大; 当θ=1.43时,受压区在距顶部3/10处相互作用力与θ=0.29相等,受压区在构件中部的相互作用力与θ=0.29相等.锥度对无肋构件的影响大于带肋构件,带肋构件的相互作用历程曲线斜率大于无肋构件,说明加劲肋提高了构件的整体性,传力更好.

外钢管径厚比取值范围为50~400,通过改变外钢管壁厚改变外钢管径厚比.THSTW-CFDST构件在弯扭比为1时的扭矩-转角曲线如图 13所示.随着外钢管径厚比增大,构件抗扭承载力和刚度均减小.当外钢管径厚比从50增大到150时,无肋构件承载力下降94.76%,带肋构件承载力下降92.16%,设置加劲肋使构件极限抗扭承载力分别提升0.94%、1.63%、1.82%、2.30%.随着外钢管径厚比增大,其延性降低,对混凝土的约束减小,当径厚比较大时,加载后期,外钢管仅中上部达到屈服,构件顶部发生明显扭转破坏,建议外钢管径厚比不大于150.

图 13 不同外钢管径厚比构件的扭矩-转角曲线

Fig.13 Torsion-rotation angle curves of various diameter-to-thickness ratio of outer steel tube members

图 14为不同外钢管径厚比时,外钢管与夹层混凝土之间的相互作用力在极限状态下沿高度变化曲线,其中,P和N分别为外钢管与夹层混凝土在受压区和受拉区的相互作用力,负号为受压区.随着外钢管径厚比增大,外钢管与混凝土之间的相互作用减小,其对带肋构件受压区影响大于无肋构件,对带肋构件受拉区影响小于无肋构件,受压区相互作用力大于受拉区,在弯矩作用下向受压区弯曲,受拉区外钢管约束混凝土裂缝扩展.带肋构件历程曲线斜率大于无肋构件,说明加劲肋的设置可以提高构件整体性.

内钢管径厚比取值范围为34~160,通过改变内钢管壁厚改变内钢管径厚比.THSTW-CFDST构件在弯扭比为1时的扭矩-转角曲线如图 15所示.随着内钢管径厚比增大,构件抗扭承载力和刚度均减小.当内钢管径厚比从34增大到160时,无肋构件承载力下降70.55%,带肋构件承载力下降72.73%.设置加劲肋使构件抗扭承载力分别提升2.85%、4.48%、1.82%、1.80%、1.54%、1.55%.

图 15 不同内钢管径厚比构件的扭矩-转角曲线

Fig.15 Torsion-rotation angle curves of various diameter-to-thickness ratio of inner steel tube members

图 16为不同内钢管径厚比时,外钢管与夹层混凝土之间的相互作用力在极限状态下沿构件高度变化曲线,其中,P和N分别为外钢管与夹层混凝土在受压区和受拉区的相互作用力,负号为受压区.随着内钢管径厚比增大,构件外钢管与混凝土之间的相互作用减小,但影响较小,综合整个构件承载力变化可知,通过减小内钢管径厚比提高构件承载力容易造成材料浪费.

不同混凝土强度等级的THSTW-CFDST构件在弯扭比为1时的扭矩-转角曲线如图 17所示.混凝土强度等级对构件抗扭刚度影响较小,随着混凝土强度等级提高,抗扭承载力有一定程度提高,但不明显.当混凝土强度等级从C60提高到C120时,无肋构件的抗扭承载力提高1.96%,带肋构件的抗扭承载力提高1.66%.设置加劲肋使构件极限抗扭承载力分别提升2.11%、1.38%、1.79%、1.82%.混凝土对带肋构件的影响小于无肋构件,这是由于无肋构件在外钢管达到屈服后,混凝土裂缝充分发展,受压区裂缝间混凝土以“受压杆”的形式继续承担荷载,而带肋构件由于加劲肋的设置,夹层混凝土形成密集的微裂缝,降低了混凝土的受压承载力.

图 18为不同混凝土强度等级时,构件外钢管与夹层混凝土之间的相互作用力在极限状态下沿构件高度变化曲线,其中,P和N分别为外钢管与夹层混凝土在受压区和受拉区的相互作用力.混凝土强度等级对构件外钢管与混凝土之间的相互作用影响较小,各构件相互作用变化趋势基本一致.

内钢管强度范围为Q420~Q690.不同内钢管强度的THSTW-CFDST构件在弯扭比为1时的扭矩-转角曲线如图 19所示.内钢管强度对构件抗扭刚度影响较小,随着内钢管强度降低,抗扭承载力减小.当内钢管强度等级从Q690降低到Q355时,无肋构件的抗扭承载力降低19.73%,带肋构件的抗扭承载力降低20.15%.设置加劲肋使构件的极限抗扭承载力分别提升1.82%、1.25%、1.40%、1.51%、1.46%.内钢管采用Q690和Q550钢材的构件,当外钢管开始屈服时,内钢管仍处于弹性阶段; 内钢管为Q355、Q420和Q460的构件,当外钢管开始屈服时,内钢管已达到屈服强度.内钢管强度越低,构件极限扭转角越小,构件越早达到极限承载力.内钢管对混凝土起到约束作用,影响构件承载力,当径厚比或空心率较大时,内钢管强度较低越容易发生局部屈曲而降低承载力.因此,为充分发挥构件材料的力学性能,建议内钢管强度与外钢管保持一致.

不同内钢管强度时,外钢管与夹层混凝土之间的相互作用力在极限状态下沿构件高度变化曲线如图 20所示,其中,P和N分别为外钢管与夹层混凝土在受压区和受拉区的相互作用力,负号为受压区.内钢管强度等级越低,外钢管与夹层混凝土之间的相互作用力越小,其在极限承载力时材料强度发挥越不充分,各构件的相互作用变化趋势基本一致.

(1)弯扭比对构件的破坏形态影响较大.当弯扭比较小时,构件受压区出现螺旋状鼓曲,发生弯扭组合破坏.当弯扭比较大时,构件破坏形态类似于受弯构件,在构件底部受压区鼓曲.带肋构件整体破坏形态与不带肋构件相似,纵向加劲肋的设置可以有效改善钢管局部鼓曲;

(2)对于WN-1构件,当弯扭比m≤0.3时,构件发生扭转破坏; 0.3<m≤0.84时,构件发生扭矩为主的弯扭破坏; 0.84<m≤6时,构件发生弯曲为主的弯扭破坏; m>6时,构件发生弯曲破坏;

(3)空心率、锥度、内外钢管径厚比对锥形高强中空夹层薄壁钢管混凝土弯扭构件的抗扭承载力影响较为显著,混凝土强度和内钢管强度对弯扭构件的抗扭承载力影响较小.