DOI: 10.15986/j.1006-7930.2018.02.012

备注

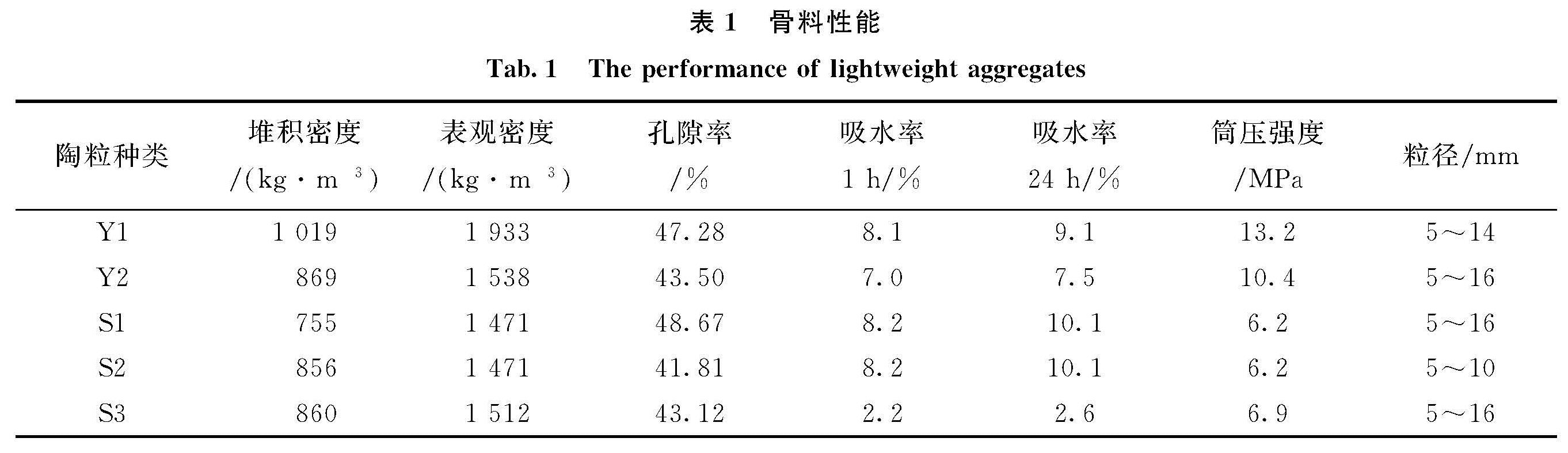

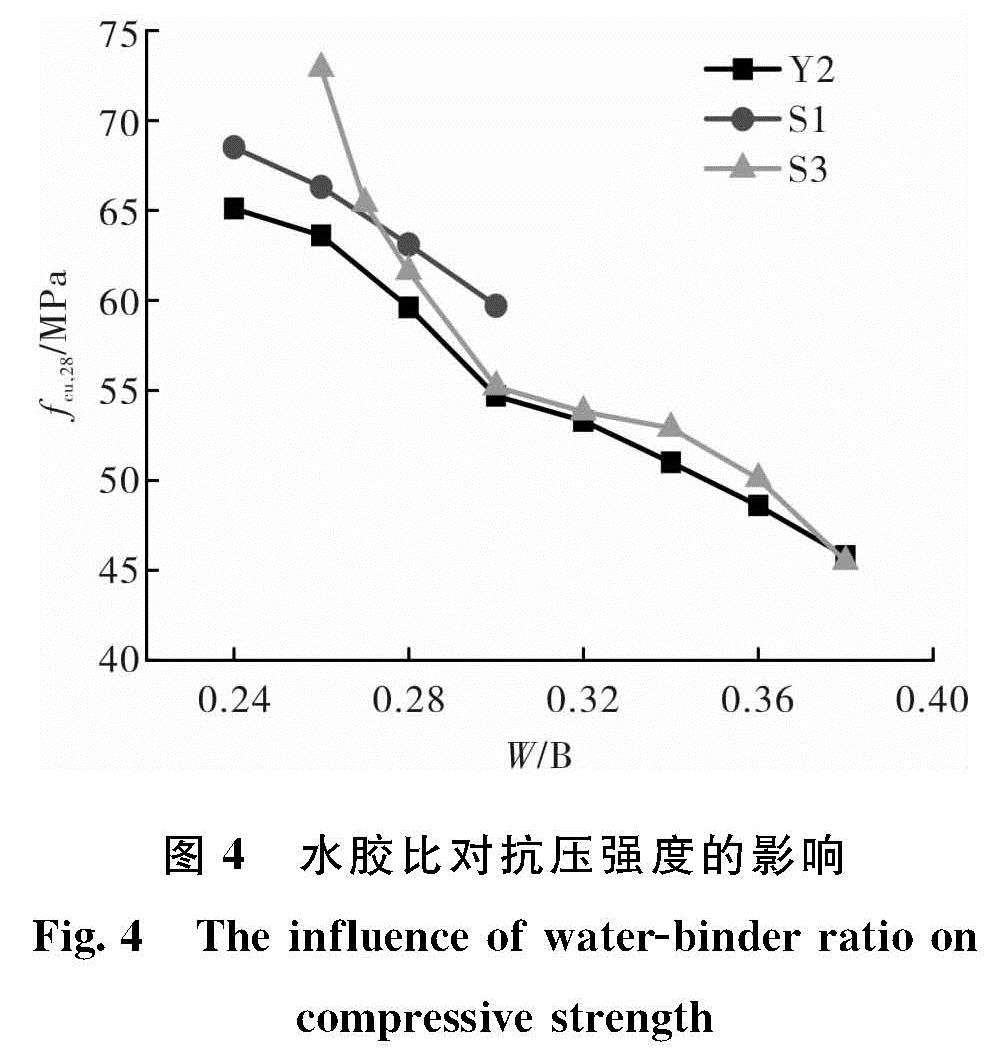

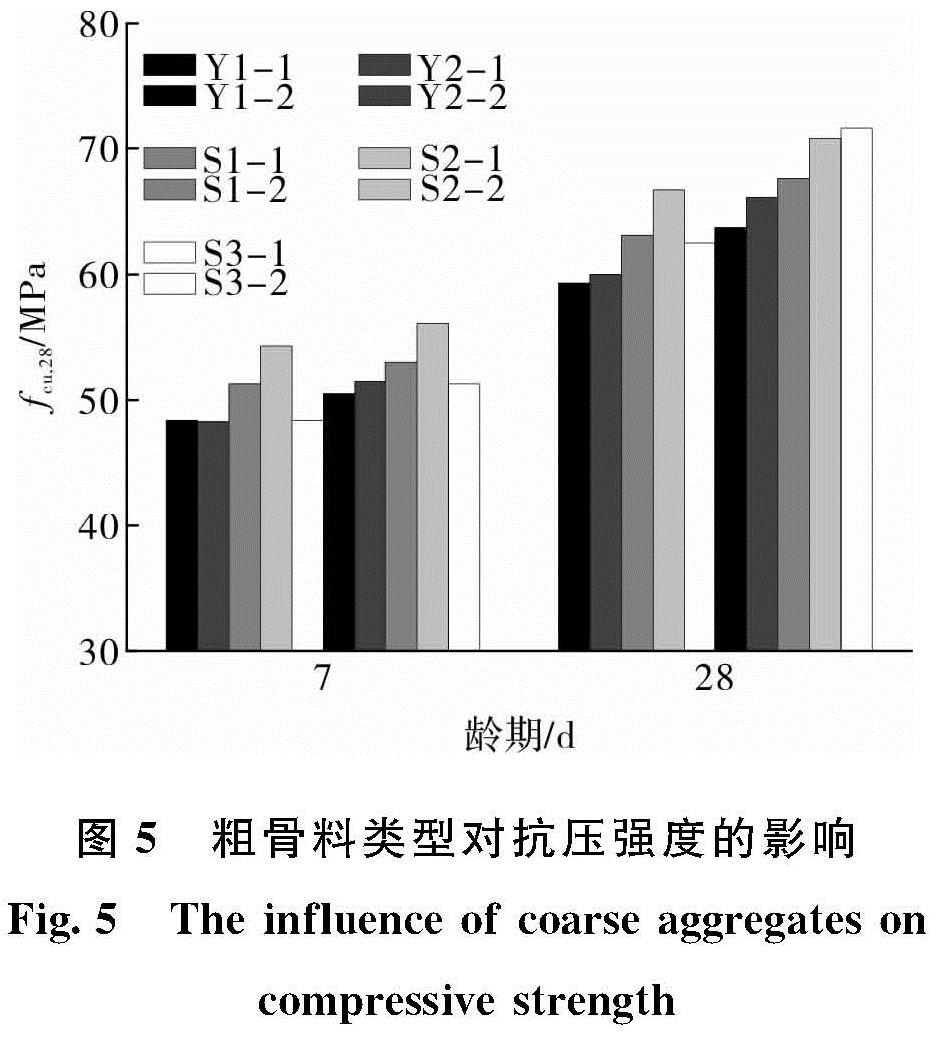

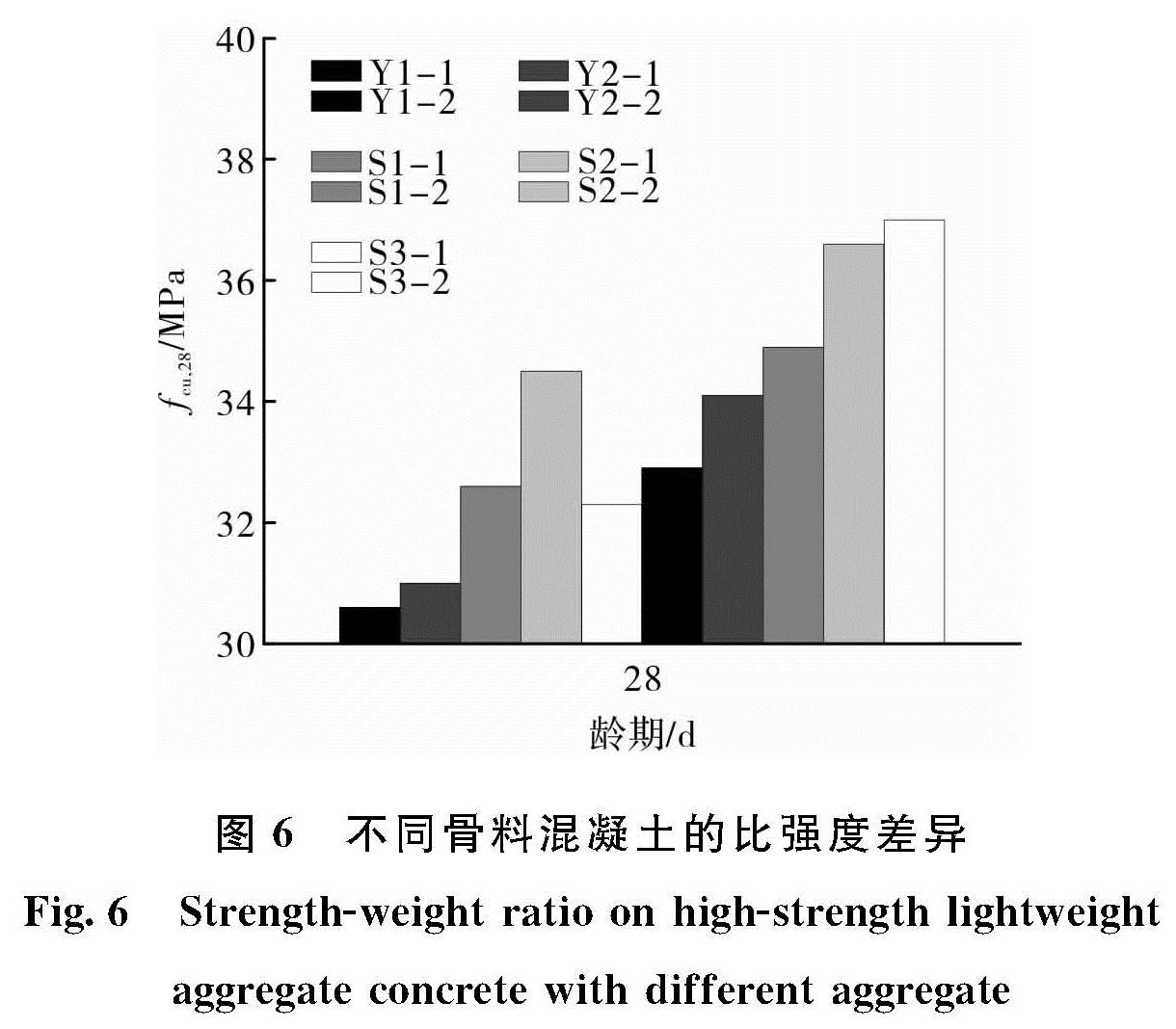

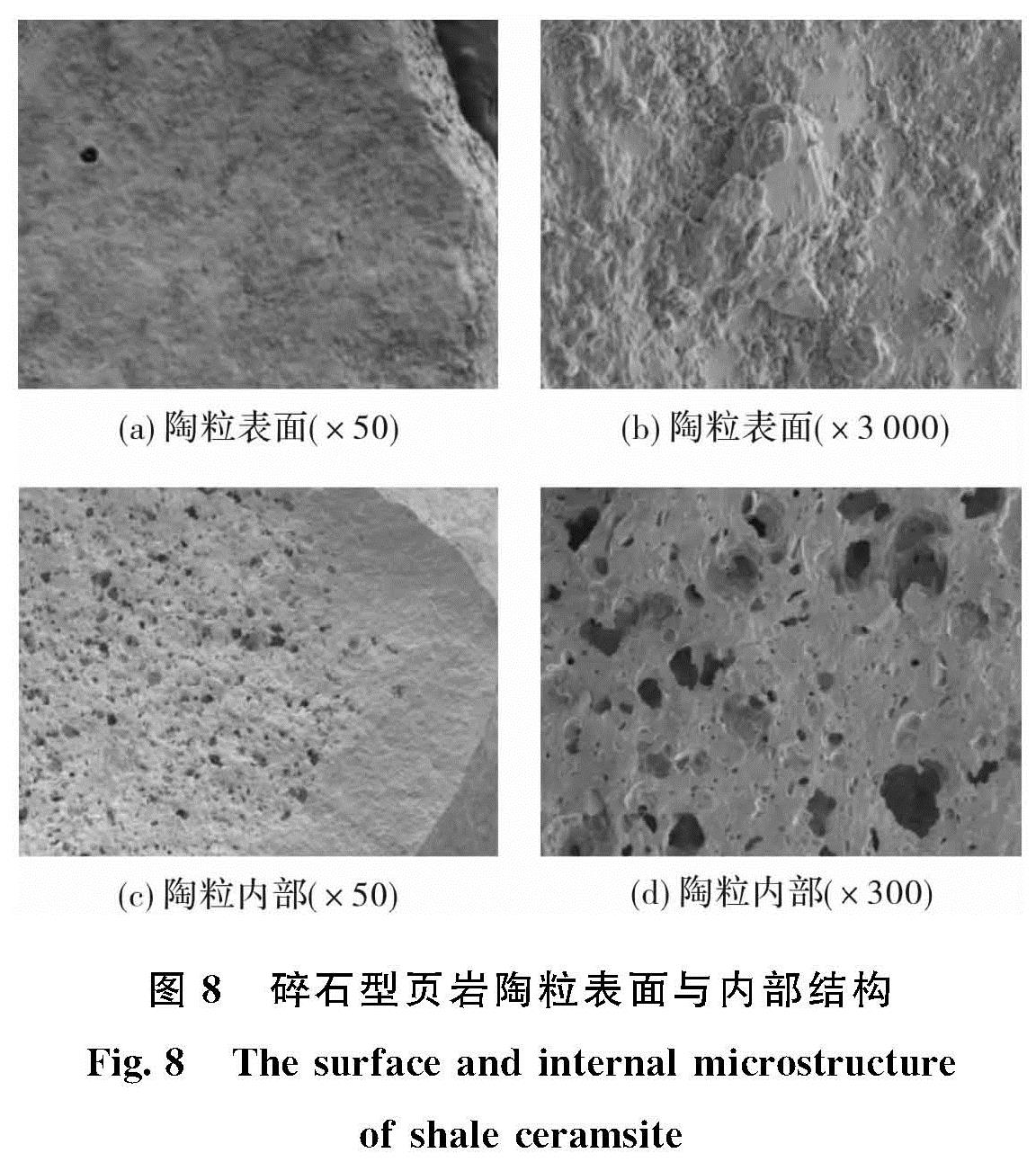

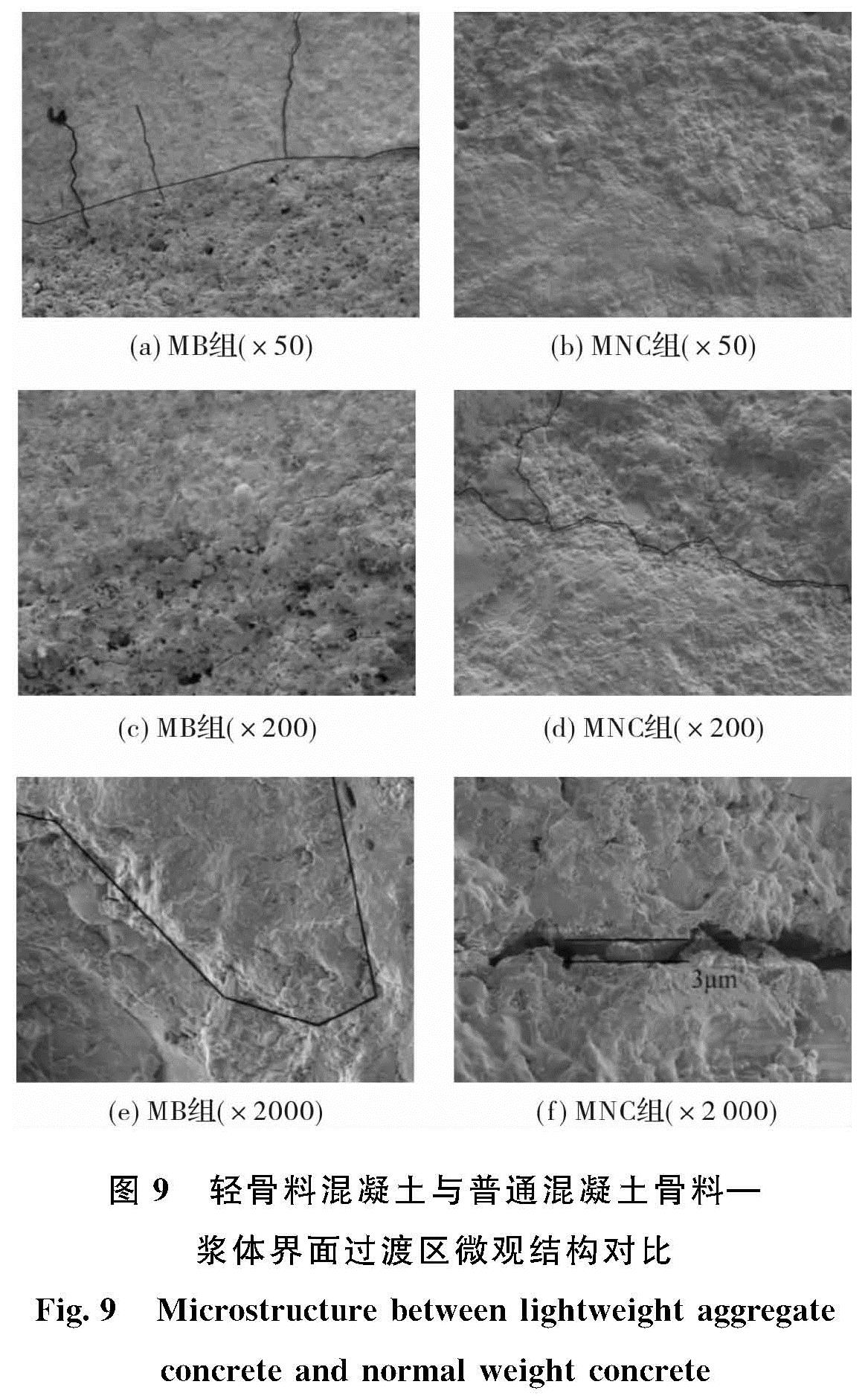

采用五种不同表观形态、强度等级的页岩陶粒,建立配合比设计方案,通过试验结果选取了合适骨料; 配制了强度等级约LC40-LC60的高强轻骨料混凝土,系统地分析了干表观密度、水胶比、骨料形态和粒径对抗压强度的影响; 进而,从微观结构出发,研究了碎石型页岩陶粒表观与内部形态,以及高强轻骨料混凝土骨料-水泥浆界面的微观结构特征,揭示了硅灰对骨料-水泥浆界面的影响机理.结果表明:900级碎石型页岩陶粒是制备高强轻骨料混凝土的最优骨料; 抗压强度随干密度的增加呈现上升趋势,随水胶比的减小而提高,硅灰的加入可以明显提高抗压强度,但受粗骨料强度制约; 轻骨料混凝土骨料-水泥浆界面区的黏结强度较普通混凝土好,适量的硅灰可以改善界面过渡区,增加骨料的三维受压作用,提高轻骨料混凝土强度.同时,LC60级高强轻骨料混凝土破坏面不再光滑,与低强度的轻骨料混凝土存在差异.

Five types of shale ceramists with different apparent shapes and strengths were used to produce the lightweight aggregate concretes(LWAC). The most appropriate aggregate for the LWAC were determined through analyzing the results of compression tests. The high strength lightweight aggregate concretes(HSLAC)of about LC40-LC60 were prepared to investigate the influences caused by the shape and the diameter of aggregate, the dry apparent density, and the ratio that water to binder on the compressive strength of LWAC. Further, the apparent and the inner morphology of the crushed shale ceramist, as well as the microstructure features of interfacial transition zone in HSLAC were studied in terms of the micro-scale, besides, the action mechanism of silica fume on the ITZ in LWAC was revealed. The test results showed that the grade 900 shale ceramist was proved to be the most optimal aggregate for casting the HSLWC. Either the dry density was increased or the W/B ratio was decreased; an improvement in the compressive strength of LWAC was observed, and, the inclusion of silica fume caused a significant increase in compressive strength but this effect was limited by the strength of the coarse aggregate. A better bond property of ITZ in LWAC, compared to that of ITZ in normal weight concrete, was obtained in the experimental investigation. Meanwhile the properties of ITZ could be modified by a proper content of silica fume, thereby the triaxial compressive action of aggregates and the compressive strength of LWAC were improved. Additionally, the failure surface of LWAC with a strength of LC60 was not smooth, which is differ from that of LWAC with a lower strength.

![图 10 硅灰对骨料—浆体界面过渡区的影响<br/>Fig.10 The influence of silica fume on microstructureScrivener[17]](2018年02期/pic153.jpg)