DOI: 10.15986j.1006-7930.2018.03.012

备注

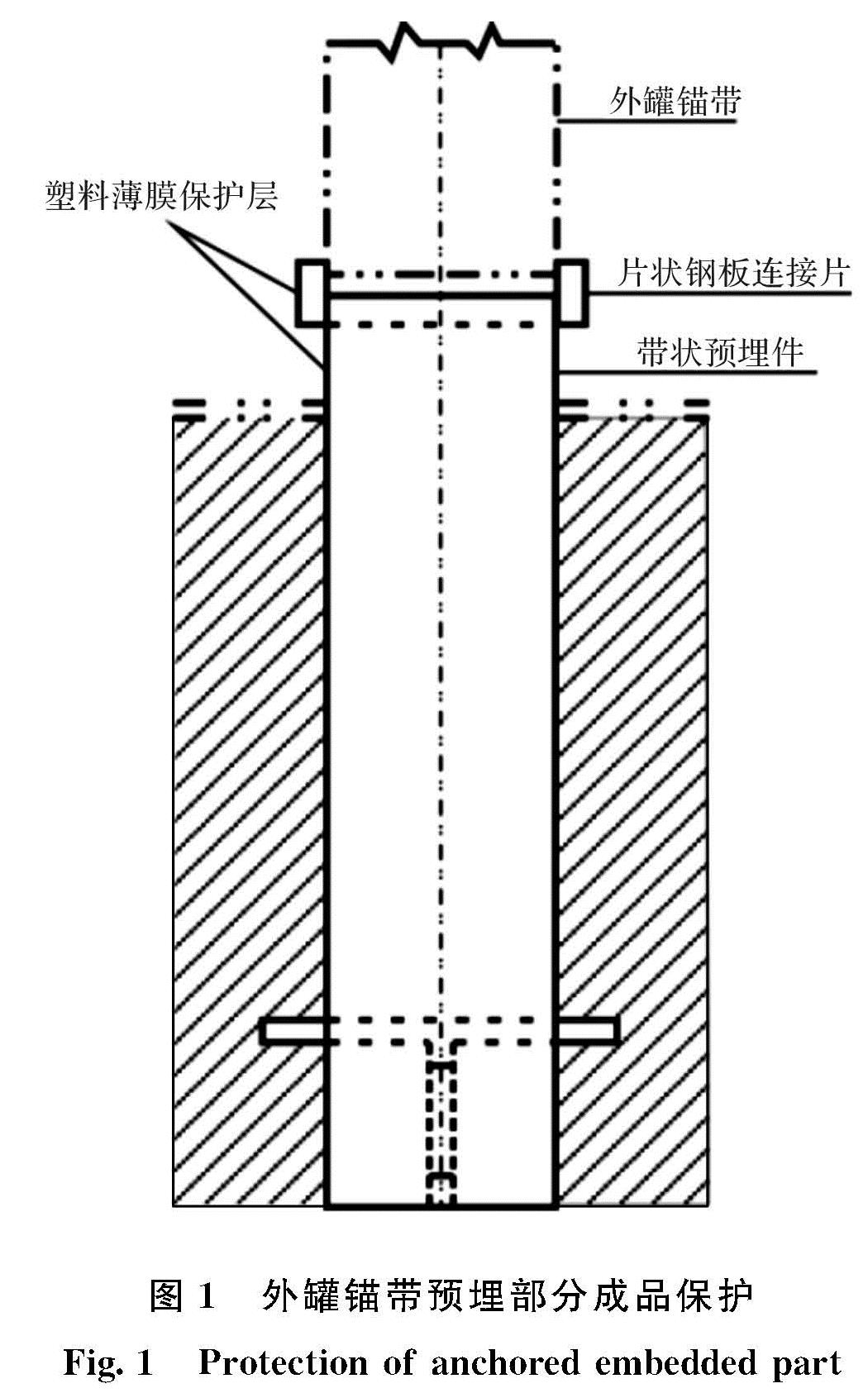

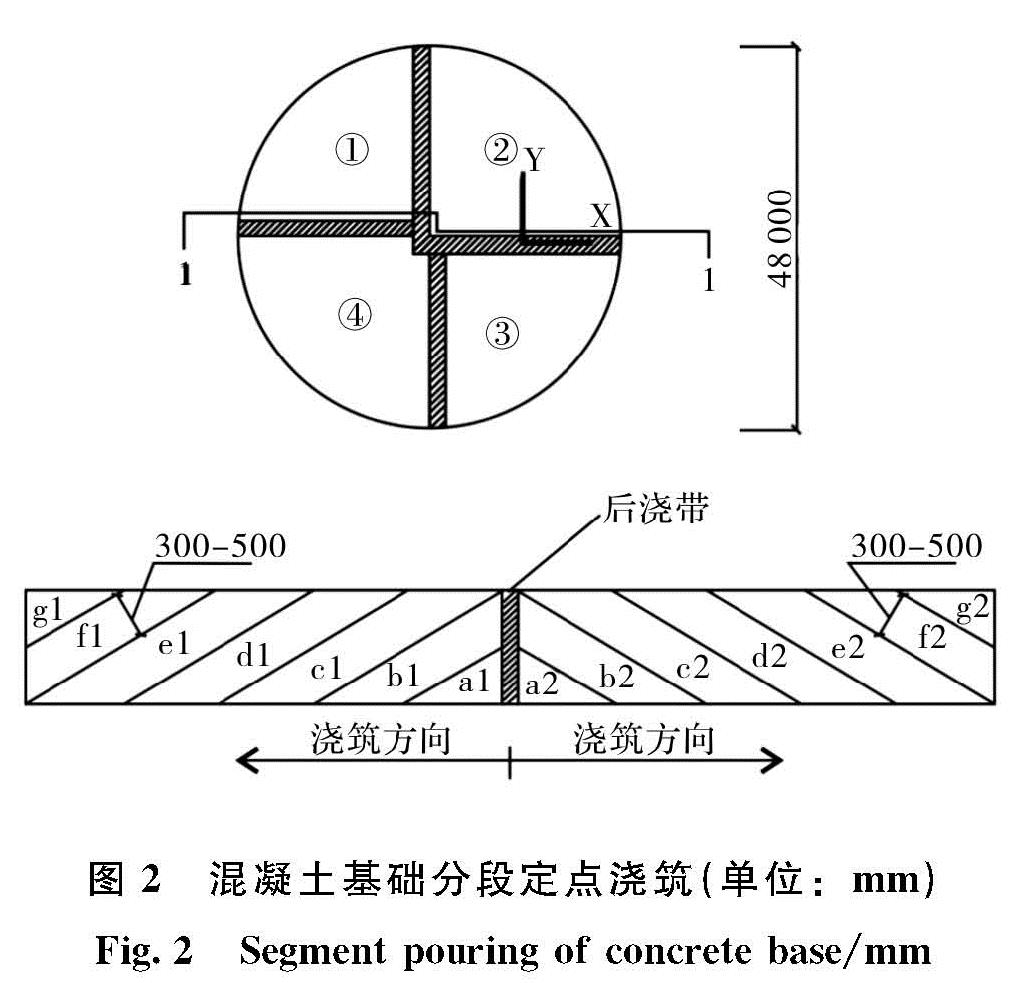

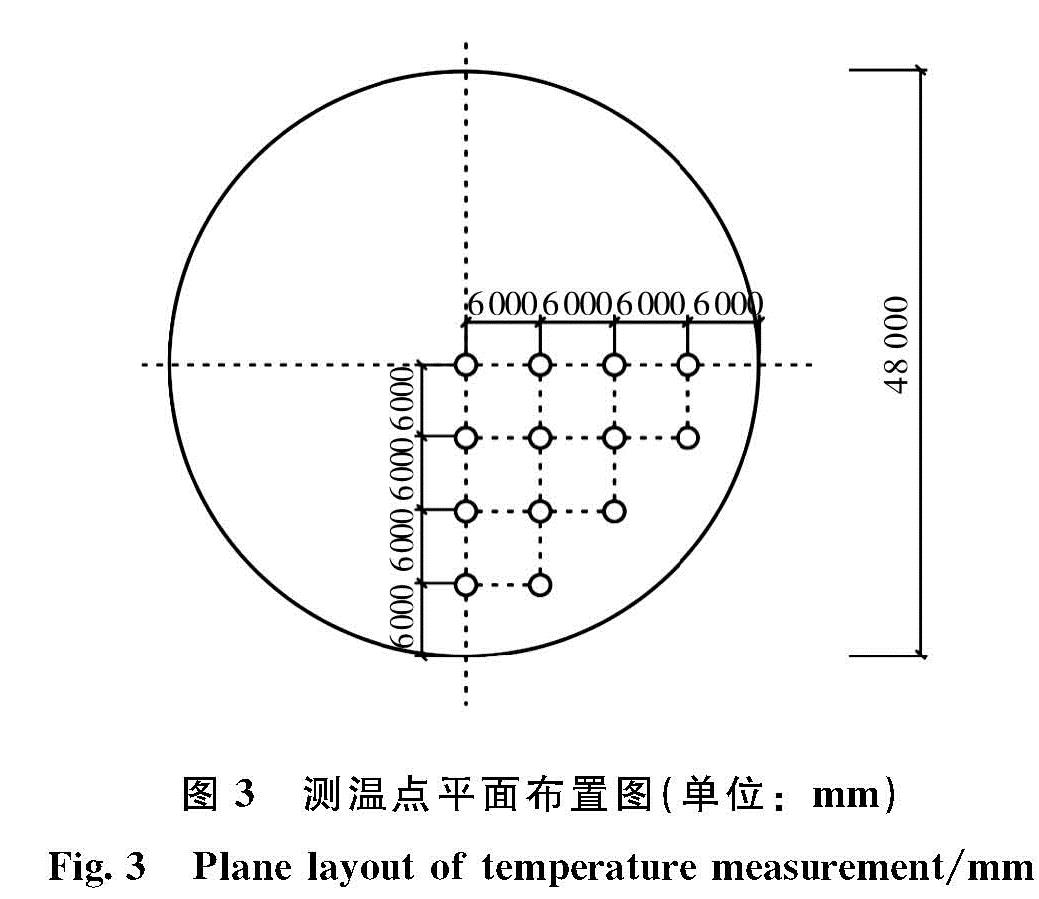

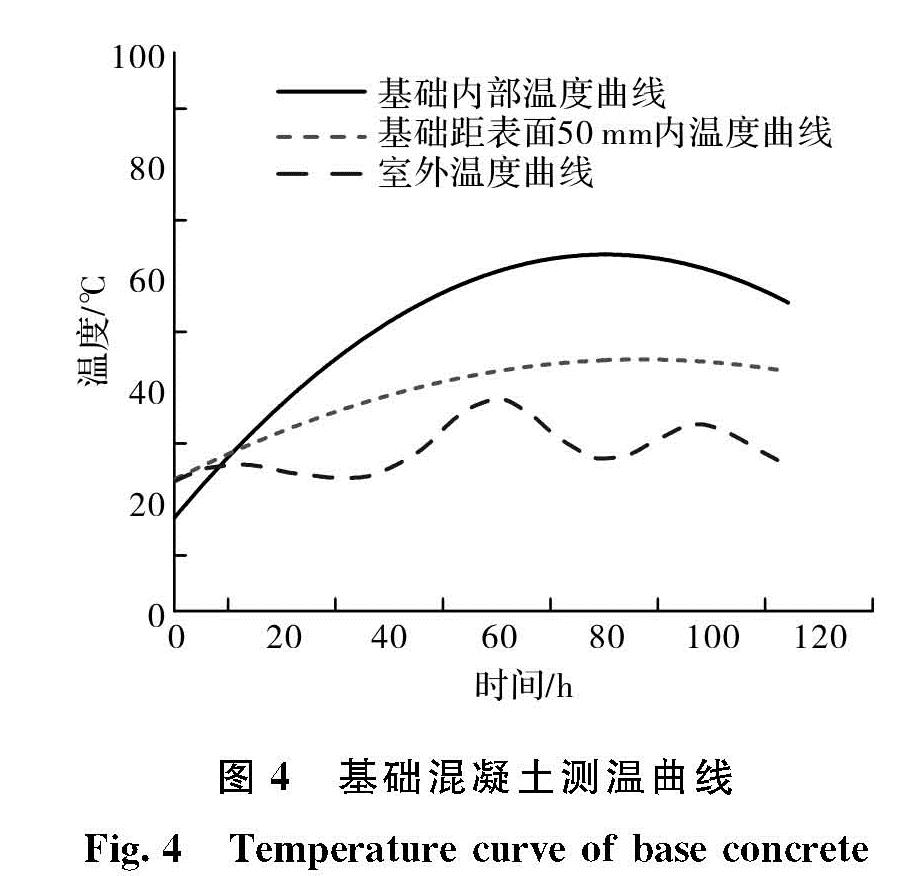

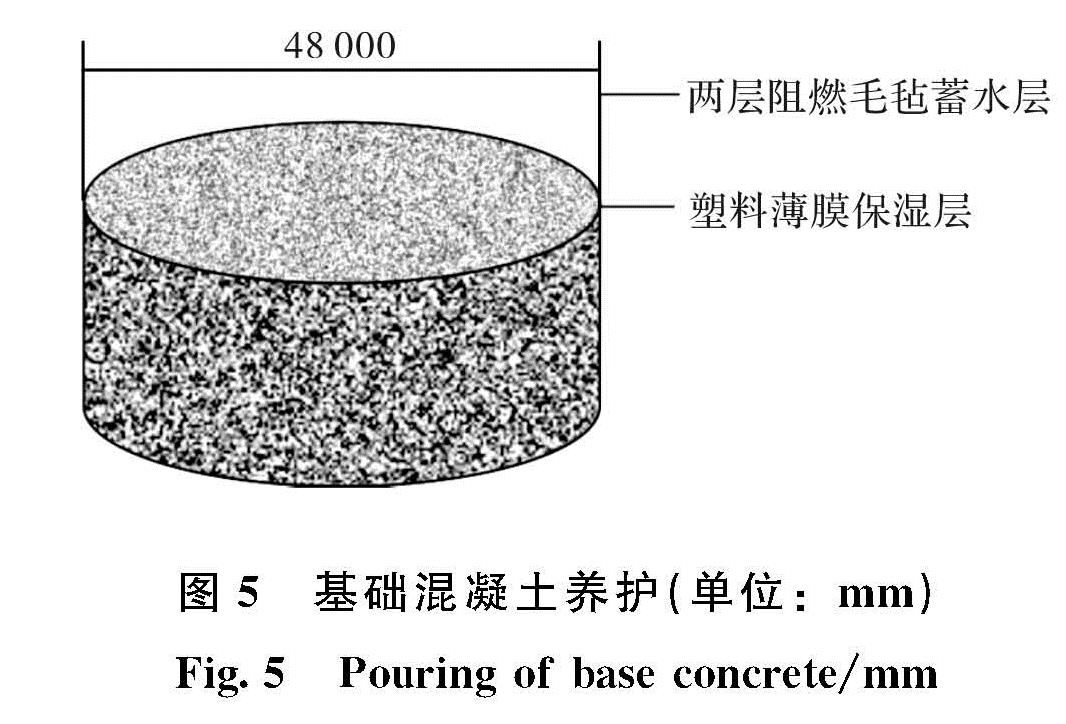

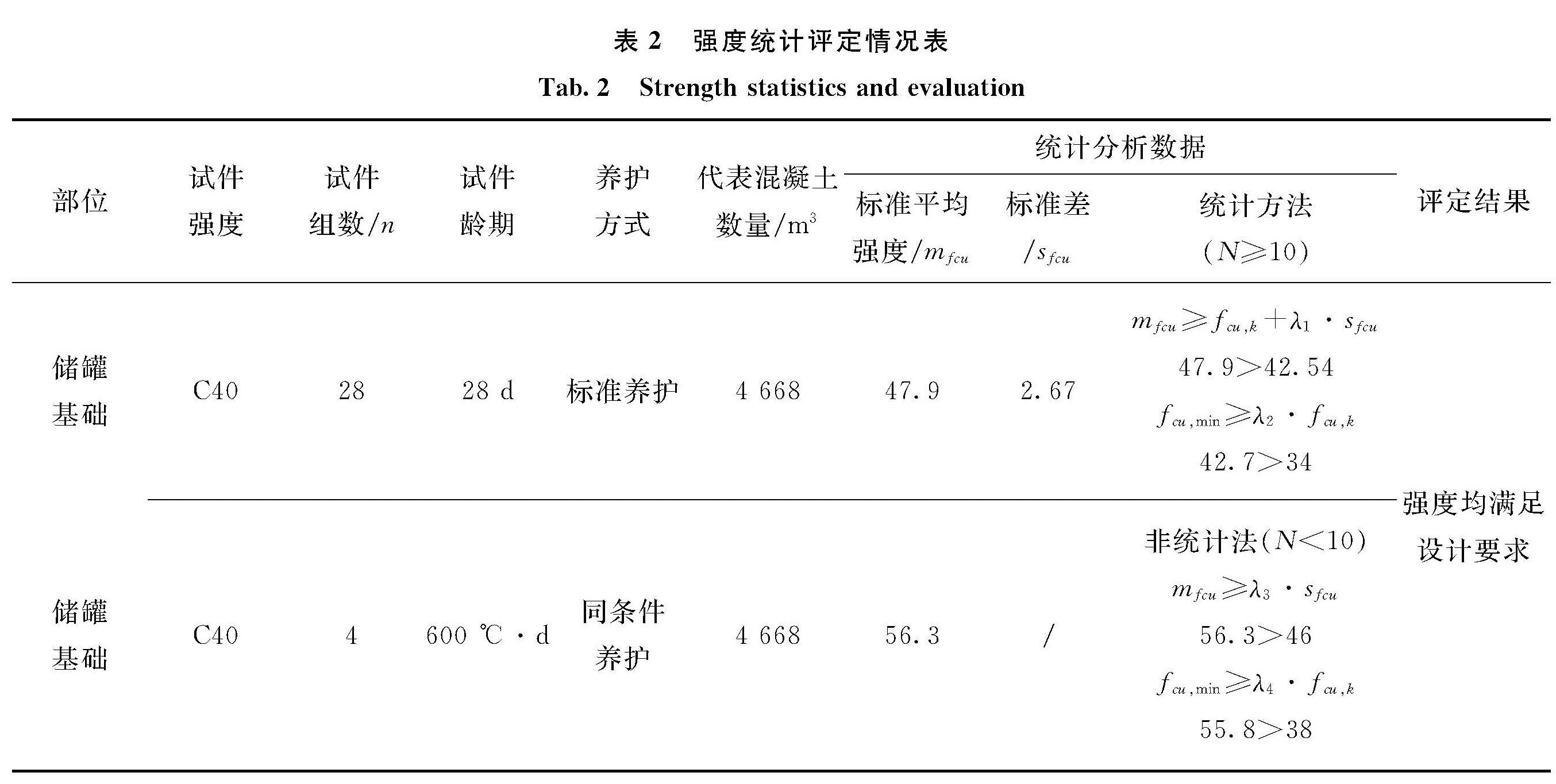

The foundation construction of liquefied natural gas(LNG)cryogenic storage tank equipment belongs to mass concrete construction. The quality control is related to the success or failure of the project because of the large quantity of concrete, the high requirement of temperature control and the great difference in the temperature of the construction. In the course of construction, the appropriate quality control targets should be determined through expert demonstration. The actual construction shows that a suitable thickness light concrete isolation layer should be installed under the bottom plate of the external tank to prevent the instantaneous frostbite of the concrete foundation caused by ultra-low temperature LNG during the leakage of the storage tank. The internal temperature rise of concrete during construction shall be no more than 50 ℃, the temperature difference in the case shall be less than 25 ℃, and the cooling rate shall be less than 2 ℃/d. In the process of concrete pouring, a pouring gradient should be set, the concrete should be casted in layers and sections, and the slump should be strictly controlled. The curing of concrete is mainly heat preservation and moisture preservation, spray curing before initial setting, and covering the insulation layer within 12 hours after pouring. The thermal insulation cover layer should be dismantled step by step. When the maximum temperature difference between the concrete surface and the environment is less than 20 ℃, it can be completely removed. At the same time, the excavation should be backfilled in time. Before pouring construction, according to the results of concrete thermal calculation and temperature control requirements, the temperature measurement scheme should be worked out to monitor the concrete entry temperature, surface temperature difference, cooling rate and environmental temperature. And all the technical measures and quality control points have achieved good construction effect.