随着我国交通量的日益增长,现有高速公路服务能力逐渐满足不了迅速增长的交通量,东南沿海地区陆续开展了大规模既有道路改拓建工程.在道路改扩建工程中,由于新老路基土材料性质和地基固结程度等存在差异,受到上覆荷载的作用,新旧路基易产生较大的差异沉降,从而引发结合部位路面开裂甚至是路基失稳等病害[1].泡沫轻质材料作为一种新型建筑材料,因其具有多孔性、轻质性、密度和强度可调节性、施工便捷以及硬化后可自立等优良特性,用于新路基填筑时能同时减小地基沉降与路基沉降[2].因此,泡沫轻质材料被用于解决高速公路拓宽路基差异沉降问题.但是,泡沫轻质材料中水泥掺量较高,生产水泥消耗了大量不可再生资源,同时造成了一定的污染.

因此,国内外学者采取黏土、粉煤灰与工业固废等替代水泥并对泡沫轻质材料的工程特性进行了一系列研究.Horpibulsuk等[3]研究了不同配合比轻质黏土的强度特性与压缩特性,进而拟合得到了强度与V/C(孔隙体积与水泥体积之比)的经验公式.Neramitkornburi等[4]对水泥固化黏土-粉煤灰轻质材料的容重、流值和强度进行了研究,粉煤灰的掺加量达到一定比例后,对于轻质材料和易性与强度均有一定程度的提高.Du等[5]通过吸水试验与抗压强度试验得到地聚合物轻质土的吸水性高于水泥基轻质土,同时强度约为水泥轻质土的2~3.5倍.Suksiripattanapong[6]等采用碱激发两种工业固废污泥与粉煤灰制备而成地聚合物泡沫轻质材料,当碱激发剂含量为复合材料的液限时,轻质材料的强度最高.Du等[7]对水泥固化锌污染黏土轻质材料的压缩性能进行了研究,含锌使材料的屈服应力、破坏强度有着明显的降低,得到Zn含量阈值为0.5%.Neramitkornburi[8]通过干湿循环试验对水泥固化黏土-粉煤灰轻质材料的水稳定性进行评价,发现粉煤灰替代量大于40%时,材料的流值、泡水强度、干湿循环后强度均有明显的提高,导致干湿循环强度损失的主要原因是黏土颗粒的膨胀与收缩.陈金威等[9]尝试了在泡沫轻质土中分别采用工业固废和高岭土代替部分水泥,试验发现掺加粉煤灰和矿粉的泡沫轻质土强度相对较高,但掺加量的提高会降低材料的抗压和抗剪强度.乔欢欢等[10]对比了掺入硅灰和粉煤灰后泡沫轻质土的性能,结果表明硅灰的掺加能够提高泡沫轻质土的强度,但由于吸水率的增加,导致其抗冻性降低; 而粉煤灰的掺入不仅提高了抗压强度,也改善了抗冻性.Bagheri[11]通过研究发现掺加适量增塑剂可显著提高泡沫混凝土混合物的稳定性.苏谦等[12]研究了循环加载对泡沫轻质混凝土力学性能的影响,提出应力-应变滞回环有不断“迁移”的现象.黄振宇等[13]以空心微珠、聚乙烯纤维为主要原材料开发了一种轻质高延性水泥基材料,密度在850~920 kg/m3的条件下抗压强度达20~33 MPa,轴向应变达到8%.

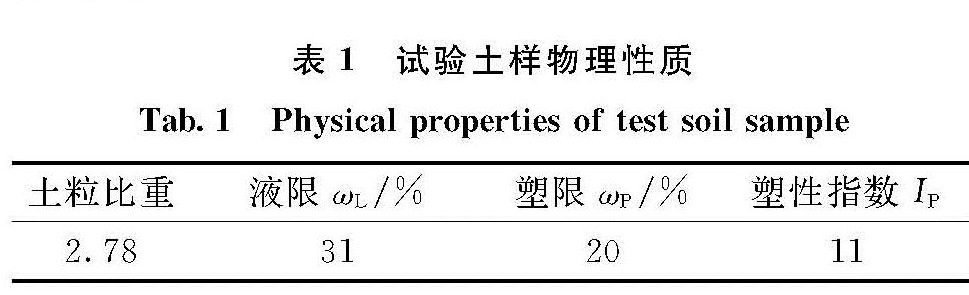

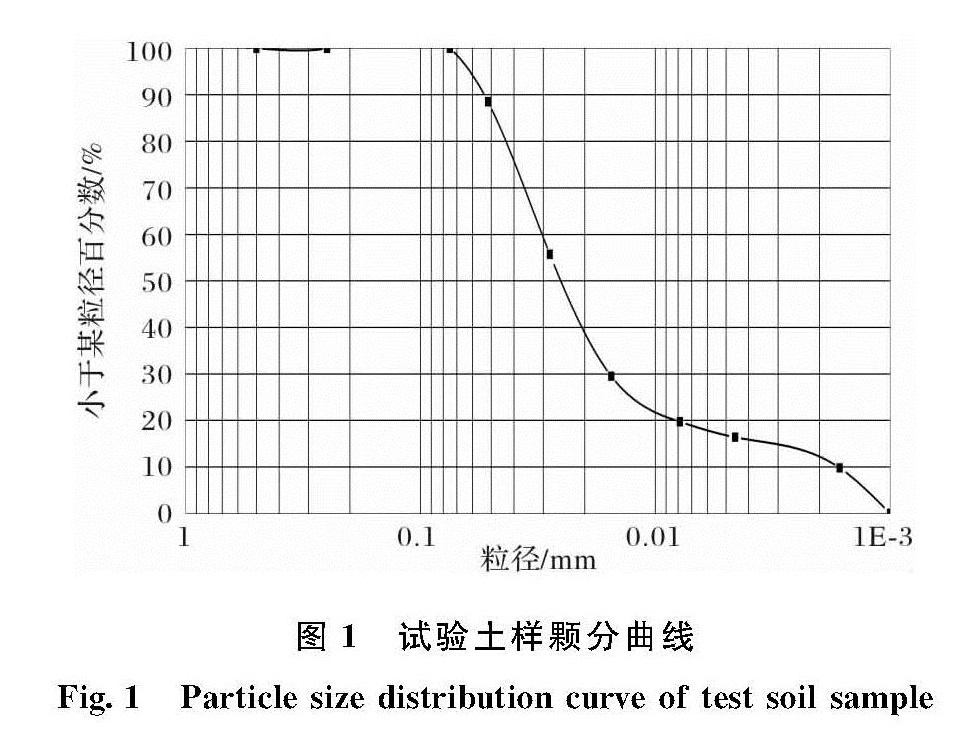

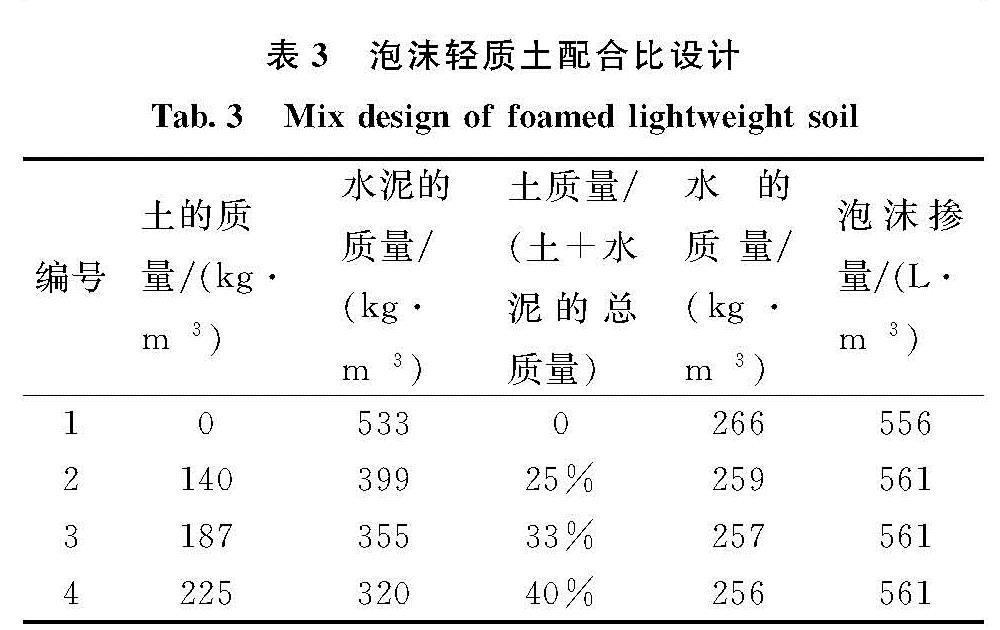

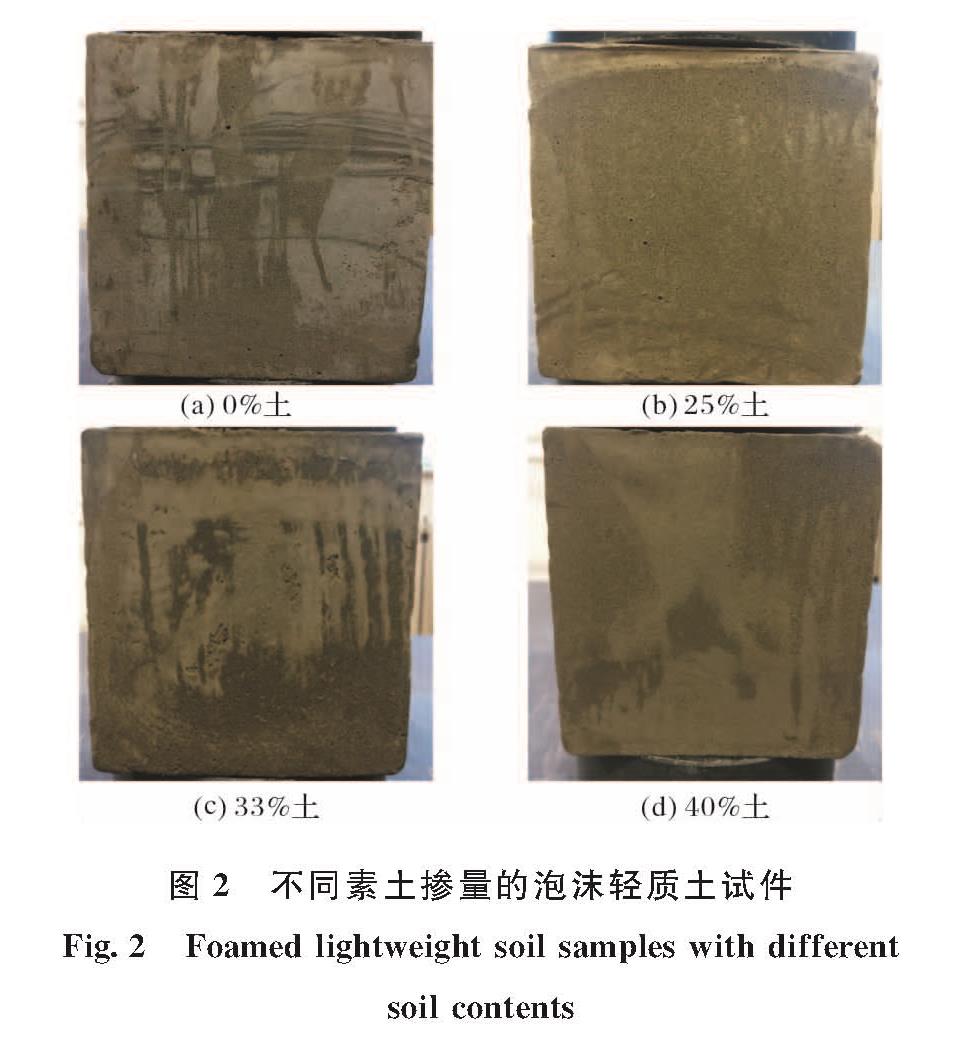

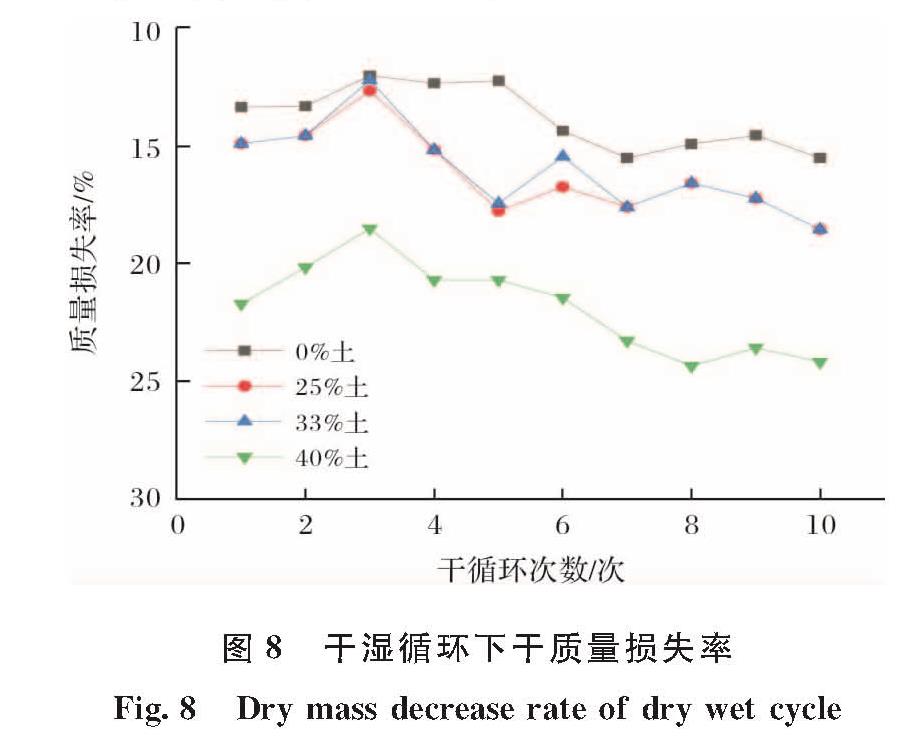

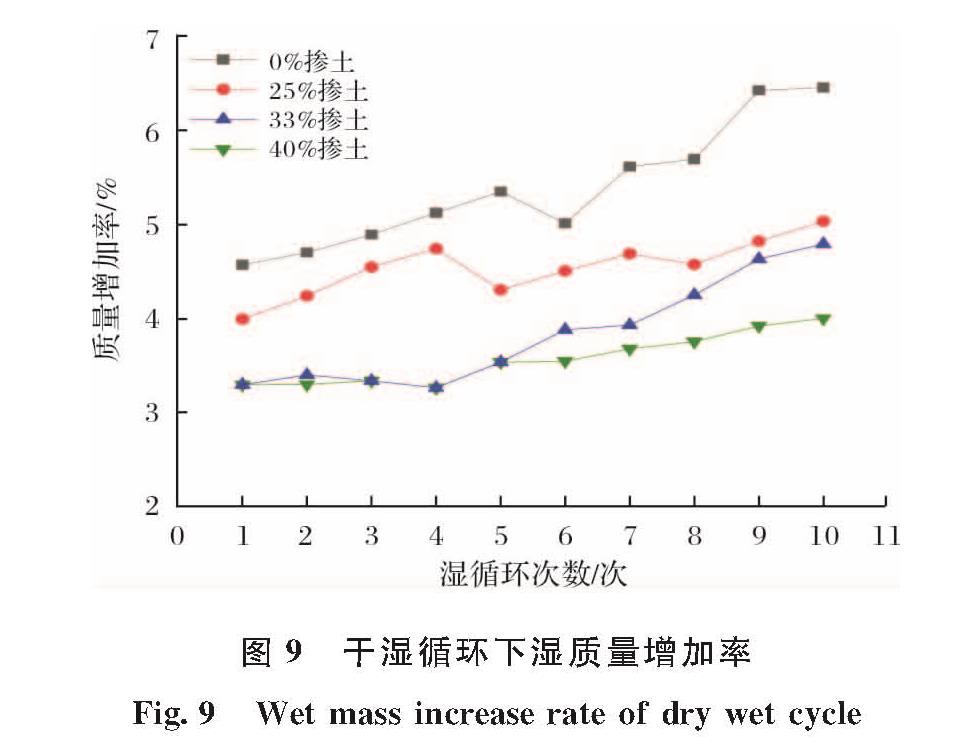

可见,目前对于泡沫轻质土的研究主要集中于材料类型和力学特性上,对于以素土为主要原料的泡沫轻质土及其干湿循环下的耐久性研究较少.泡沫轻质土作为路基材料,经常会受到雨水入渗等的影响,因此,有必要对泡沫轻质材料的干湿循环特性进行研究.本文采用黄泛区普遍分布的粉质黏土制备泡沫轻质土,对其物理力学特性和干湿循环下的性能演化进行评价,在保证长期路用性能的前提下通过减少水泥用量,以降低工程造价.