基金项目:云南省市一体化项目(202202AH210004); 国家自然科学基金资助项目(51778162); 广东省研究开发项目(2022K10072332)

第一作者:魏陆顺(1973—),男,博士,教授级高工,主要从事振动控制研究. E- mail:weils@fosu.edu.cn

(1.佛山科学技术学院 交通与土木建筑学院,广东 佛山 528000; 2.云南震安减震科技股份有限公司,云南 昆明 650211)

(1.School of Transportation, Civil Engineering & Architecture, Foshan University, Guangdong Foshan 528000, China; 2.Yunnan Quakesafe Seismic Isolation Technologies Co., Ltd., Kunming 650211, China)

rubber vibration isolation bearing; vertical stiffness; lateral deformation; fatigue performance

DOI: 10.15986/j.1006-7930.2023.01.005

TOD(Transit-Oriented Development)开发模式在国内一线城市飞速发展.在TOD模式下,轨道交通产生的振动通过隧道或桥墩传至地基进一步传至周边建筑,使得TOD上盖建筑及邻近建筑振感明显,并诱发结构二次噪声,导致TOD上盖建筑使用舒适性降低.因此,适用于TOD结构使用的多功能隔振装置研发成为振动控制领域的热点和难点.目前,针对振动现象,有橡胶隔振和钢弹簧隔振两种方式,钢弹簧性能和理论计算均较成熟,而橡胶隔振其理论仍是空白; 针对地震,主要是隔离水平向地震作用.在水平隔震同时,隔离竖向振动,减轻城市交通等环境振动的影响,是亟待解决的难题.

在结构的三维隔震(振)方面,已有学者开展了研究.现阶段,国内外多数学者的三维隔震研究是伴随三维支座开发研究进行的.为解决水平隔震和竖向交通振动问题,1996年Fujita S等[1]研究了一种由螺旋弹簧和橡胶支座组合形成的三维隔震体系,为克服结构摇摆问题,结构周围采用支撑支座.2000年,S Yabana[2]对厚层的橡胶支座进行三维隔震性能研究.2004年,熊世树等[3]提出了一种铅芯橡胶碟簧三维隔震支座(3DB),并对其性能进行了试验和理论研究,同期,孟庆利等[4]研究了竖向半主动隔震装置的三维隔震系统.2004年,作者发明了一种新型的三维隔震减振支座,可实现水平隔震和竖向隔振功能,并在实际工程中得到了应用[5].综上可知,在竖向被动隔振方面,市场上有成熟的橡胶减振支座和钢弹簧两种方式; 在水平隔震方面,成熟的方案是整体结构水平隔震技术.对于整体结构采用竖向隔振时,须满足地震作用下结构不会出现大的摇摆反应.此方面研究成果较少,仍处于起步阶段.

在橡胶支座理论方面,为准确计算隔震支座的竖向性能和水平性能,Gent和Lindley(1959,1970,1974年)[6-8] 最早开始了钢板对橡胶约束作用下支座特性研究,在假设橡胶体积不可压缩、垂直压缩变形引起橡胶鼓凸,其变形量与圆板中心成正比,并采用抛物线模拟变形剖面的条件下,推导橡胶隔震支座的竖向压缩性能、水平剪切性能和弯曲性能计算公式.上述推导是基于竖向变形较橡胶总厚度是微小变形.对于橡胶隔振支座,钢板对橡胶约束大大减小,上述条件已不再成立.基于上述现状,本文开展橡胶隔振支座理论和试验验证相关研究.

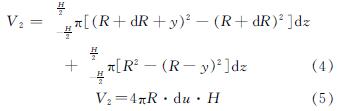

本部分推导支座侧向变形计算.对于单层橡胶体,中孔半径为r0,外径为D,变形前橡胶层厚度为tR.取环形单元dR分析(见图1),变形后高度为H,变形前后环形单元体积不变,变形前体积为

V=2πR·dR·tR(1)

变形后体积包括2部分,高度为H的环形体积为

V1=2πR·dR·H(2)

上述2部分体积变化为

dV=V-V1=2πR·dR·δV(3)

式中:竖向变形δV=tR-H.

变形后鼓出部分中,du为鼓出最大位移,取变形后鼓出部分沿高度不变,y=du,变形后鼓出部分体积为

环形单元变形前、后体积不变,可得

dV=V2=2πR·dR·δV(6)

du=(δV)/(2H)·dR(7)

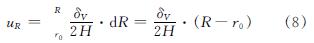

对于R位置,鼓出值为

Lindley推导的uR=3/4(δV)/H·(R-r0),其计算结果较式(8)大.由式(8)可知,橡胶隔振支座向外鼓出和向内鼓出计算一样,即中孔鼓出量与外围鼓出量相同.

建筑橡胶隔震支座竖向刚度理论计算中,支座刚度大,橡胶竖向变形和侧向变形均较小,推导的竖向刚度理论计算公式得到的支座刚度为恒定值,与竖向荷载或变形无关.而橡胶隔振支座竖向变形大,建筑橡胶隔震支座竖向刚度理论计算公式不再适用.本部分利用弹性力学经典理论,推层橡胶隔振支座竖向刚度理论计算公式.

橡胶隔振支座竖向受力和变形为轴对称空间问题,坐标系见图1,本部分采用位移求解,环向位移采用式(8),即

uR=(δV)/(2H)·(R-r0)(9)

各应变量为

上式中uz为竖向变形分量,对应体积应变为

不计体力,位移分量应满足下述方程为

设uz方向变形满足平截面假定,式(14)可简化为

((2-2u)/(1-2u))(d2uz)/(dz2)=0(15)

式(15)对应结果为

uz=Az+B(16)

竖向位移对应边界条件为(uz)z=0.5H=δV,(uz)z=-0.5H=0,由边界条件确定的式(16)中系数A、B值,即

uz=(δV)/Hz+(δV)/2(17)

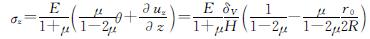

式(17)为竖向位移方程,由此可得竖向应力为

(18)

(18)

取任一界面,同平衡方程得

式中:R、r为橡胶隔振支座变形后的状态,即R=D/2+uR,r=r0-uR.

设α=πE/(1+μ)((0.5D+r0-μ·r0)(0.5D-r0))/(1-2μ),

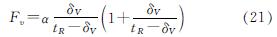

对于确定的橡胶隔振支座,α为常数,有

由式(21)可得竖向刚度公式为

(22)

(22)

由式(22)可知,随竖向压缩变形增加,竖向刚度会逐步增大,竖向刚度呈现非线性特性.式(22)采用弹性力学理论得出,由于橡胶材质的弹性模量在不同应力下为非恒定常数,表观弹性常数还需经相关试验修正确定.

对于橡胶隔振支座,由于橡胶层较厚,钢板对橡胶约束大大减小,用于建筑抗震橡胶支座的竖向刚度计算公式已不再适用.论文针对支座侧向鼓出采用矩形变形模拟较抛物线有更高的计算精度,且中心孔的鼓出量与外围鼓出量相同,此计算方法可作为隔振支座尺寸设计使用.

为导出竖向刚度计算公式,本文依据经典弹性力学理论,采用位移求解方法,推导了相关计算公式.公式表明,竖向刚度与竖向压缩变形有关,且与竖向刚度试验结果趋势一致.由于橡胶应力、应变关系的非线性特性,论文推出的计算公式与实际还存在较大偏差,建议使用本公式时,应结合不同橡胶材料特性和试验修正共同确定.

200万次的疲劳试验结果表明,橡胶隔振支座是一种良好的隔振装置,且支座承载力大,高度小,是一种较理想隔振选择方案.