基金项目:陕西省创新能力支撑计划-创新团队基金资助(2020TD-005); 陕西省自然科学基金资助(2021JM-373)

第一作者:陈 兴(1974—),男,高级工程师,主要从事土木工程施工技术管理工作.E-mail:437086155@qq.com 通信作者:王怀正(1997—),男,硕士研究生,主要研究隧道施工技术.E-mail:wanghzzy@163.com

(1.中交第二公路工程局有限公司,陕西 西安 710119; 2.西安建筑科技大学 隧道与地下结构工程研究所,陕西 西安 710055; 3.西安建筑科技大学 土木工程学院,陕西 西安 710055; 4.陕西省岩土与地下空间工程重点实验室,陕西 西安 710055)

(1.China Communications Second Highway Engineering Bureau Co. Ltd, Xi'an 710119, China; 2.Institute of Tanhel and Undergrourd Structure Engineering of Xi'an Univ. of Arch. & Tech., Xi'an 710055, China; 3.School of Civil Engineering, Xi'an Univ. of Arch.& Tech., Xi'an 710055, China; 4.Shaanxi Key Laboratory of Geotechnical and Underground Space Engineering, Xi'an 710055, China)

tunnel entrance; comparative analysis; numerical simulation; stability

DOI: 10.15986/j.1006-7930.2023.03.006

随着铁路交通基础设施建设的快速发展,隧道工程不可避免地修建在山岭地带.而山岭浅埋隧道通常地处岩体风化程度高、节理分布复杂等地段,隧道的洞口端和周边仰坡易产生开裂、滑坡甚至崩塌等危害.若隧道洞口处理不当,将严重影响隧道的整体稳定,甚至引起隧道坍塌[1-4].因此,保证隧道洞口的稳定在隧道结构设计中具有极为重要的地位.

因此,近年来各国学者对隧道洞口施工方案优化、支护方式设计、边坡治理措施等进行了大量分析[5-6].为确保隧道洞口段施工方案的合理性,李东顺等[7]基于“V”形冲沟高边坡黄土隧道提出四种隧道施工方案,经过对比分析认为单侧壁导坑法操作性更强.XU等[8]认为浅埋隧道开挖方向对隧道稳定性影响较大,认为向坡开挖相较于背坡开挖而言,隧道围岩易产生塌方现象.卢光兆等[9]认为浅埋偏压隧道洞口岩体难以形成稳定的自然拱,提出采用带有竖向支撑的中隔壁法或双侧壁导坑法更能保证隧道变形稳定.崔光耀等[10]、YU等[11]分析隧道洞口端衬砌的应力特征后,对洞口支护结构进行了优化.隧道洞口施工不可避免的会遇到边坡治理问题,以下学者对边坡治理措施进行了相关研究.孙文等[12]对隧道洞口端边坡破坏模式进行分析,认为缓坡易发生坡底处的剪切破坏,而陡坡易发生坡顶的拉裂破坏.HU等[13]、TIAN等[14]对坡体前缘部分的变形进行了研究,提出采用地面注浆钢管或抗滑桩的方式抑制洞口上层土体位移.FAN等[15]对隧道下穿软弱夹层边坡的工程实例进行研究,探讨了锚索和抗滑桩加固对边坡滑动和隧道应力的控制效果,得出锚索加固措施对减小边坡滑移更有效.锚索、抗滑桩是防止边坡位移的重要治理手段,但由于施工环境愈加复杂,采用单一的治理措施往往不能满足施工要求,为此刘运泽等[16]对隧道洞口古滑坡堆积体边坡进行了研究,提出采用锚杆、锚索、抗滑桩以及路基反压相结合的综合治理措施.陈舞等[17]、谢伟东等[18]认为强降水等极端天气对岩土体弱化效应明显.因此,为保证强降雨条件下隧道边坡的稳定性,Li等[19]提出的抗滑桩与层内压实回填相结合的治理措施能够有效防止滑坡.

上述学者对隧道洞口稳定性进行了大量研究,但山岭隧道地质复杂,采取不合理的加固措施将严重影响隧道施工安全.因此,还需对隧道洞口加固措施的合理性进行进一步研究.本文依托格鲁吉亚F3标5号公路隧道项目,提出锚网喷支护代替微型桩墙,将洞口向后移动3 m,利用天沟、边沟保证排水通畅等建议.通过有限元分析软件MIDAS-GTS对隧道出口段建立三维模型,分析在两种加固方案下,隧道开挖引起的围岩及衬砌的位移场,应力场的特征变化.并结合现场监测数据分析隧道围岩稳定性,为类似的隧道工程项目提供一定的参考.

格鲁吉亚公路Khevi-Argveta段(E60公路路线)位于格鲁吉亚地块的中部.它由一个结晶基底构成,与格鲁吉亚山间平原的一个隆起部分Zemo-Imereti高原重合,暴露于Loki、Khrami和Dzirula地块中.项目线路始于Zemo-Imereti高原,沿着Dzirula河的沟壑由东向西延伸至Kolkheti低地的东部山丘.线路起点处山岭被Dzirula和Kvirila河及其支流分割,其特点是春季洪水泛滥,夏季水位较低,导致地形起伏破碎.沟壑深度自东向西逐渐减小,最深处达300 m.地层岩性十分复杂.

格鲁吉亚F3标5号隧道多次穿越河床及南北走向的构造线,地质复杂.该隧道为双洞双线式隧道,设计总长为867 m,隧道里程为DK6+438~DK7+305.隧道最大埋深达27.3 m,最小埋深为1 m,左、右隧道相距10.31 m.洞口地层由元古代结晶基底的侵入岩和变质岩构成,主要为重度风化的花岗岩及花岗闪长岩.工程概况如图1.

格鲁吉亚F3标5号公路隧道洞口原设计采用直径为240 mm、间距0.50 m的微型桩墙支护,并用直径168.3 mm、厚10 mm的型钢加固.现设计采用直径为32 mm的圆形锚杆与挂网喷射厚20 cm的C30混凝土形成锚网喷边坡支护.通过锚喷网代替微型桩墙,并将洞口位置向后移动3 m,利用锚杆对岩体施加拉应力,封闭节理,提高了坡面的自承能力.并且减少岩土体的开挖量和固废弃土有利于缩短工期,也降低了对环境的破坏,如图2所示.为探究两种方案的施工稳定性,利用有限元软件MIDAS-GTS建立三维模型,模拟隧道施工过程,对其进行应力与变形分析.

根据隧道模型的相关设计理论,隧道开挖对围岩应力状态的影响区域为开挖轮廓线外3~5倍洞室宽度.为避免模型因边界条件而影响计算结果的准确性,确定模型在X(横向)、Y(竖向)、Z(纵向)三个方向上的尺寸为140 m×130 m×90 m.岩土体划分为4×4网格,隧道衬砌等支护结构划分为1×1网格.模型的地表为自由面,其他平面施加法向约束.模型施加岩土体自重,地形构造应力影响较小不予考虑.两种洞口支护加固方案整体模型对比见图3所示.

在MIDAS-GTS有限元模型中,因不分析桩土摩擦力,采用植入式梁单元模拟微型桩及锚杆,无需设置界面单元,岩体为重度风化的花岗岩,块体间填充粉质黏土,采用莫尔-库伦本构模型,隧道喷混等支护结构采用弹性本构类型,隧道岩土及各材料的参数根据地质报告资料,按照刚度等效原则设置,如表1所示.

对于两种支护方案下的三维模型施工顺序为:

(1)仰边坡开挖:为了防止岩体发生掉块或塌落,首先进行洞口边仰坡开挖.对于微型桩墙支护设计方案,坡面沿z轴自上而下分为四级开挖,开挖完成后利用直径240 mm、间距0.50 m的微型桩形成微型桩墙支护,并用直径168.3 mm、厚10 mm的型钢加固.对于锚网喷支护设计方案,坡面沿z轴自上而下分3次开挖,每级土体开挖完毕后,均采用C30混凝土进行喷射,并利用直径32 mm实心圆形截面的锚杆与挂网喷射厚20 cm的C30混凝土形成锚网喷边坡支护.支护结构可与岩土体共同受力,从而减小岩土体变形;

(2)明洞建设:边坡支护完成后按照洞口设计要求破除洞口处的混凝土支护,进行隧道开挖前明洞建设;

(3)隧道洞口段施工:两种洞口支护方案的隧道开挖及支护阶段定义相同.对左、右隧道进行首次开挖,开挖进尺为6 m.为防止岩土体由于首次开挖尺寸过大而发生较大变形,对洞口段进行支护,支护层厚度为0.9 m,支护方式采用型钢拱架及C30混凝土进行喷射;

(4)隧道后续开挖:采用挖掘机对整条隧道进行全断面开挖,开挖进尺为3 m.利用C30混凝土进行初期支护,以免隧道在开挖过程中由于自稳性下降而导致坍塌.最后,利用C35混凝土对隧道进行二次支护并对仰拱施作初支,仰拱支护层厚度为0.8 m,拱顶支护层厚度为0.65 m,以免隧道开挖过程中仰拱受到两侧岩土体挤压而隆起.

隧道围岩的稳定性即地下洞室周围岩体的稳定程度,目前,对于稳定性的分析有数学力学计算方法、数值模拟方法和围岩稳定性分类法等.本节将通过对微型桩墙支护设计与锚网喷支护设计下,隧道开挖引起的围岩位移变形及应力的对比来分析隧道围岩稳定性.

由于此工程隧道洞口仰坡较平缓,沿隧道开挖方向即Y轴方向的位移不作考虑,主要针对隧道横、纵两个方向即X轴与Z轴方向的位移变形进行比较分析.隧道开挖进洞100 m后围岩的横向水平位移和纵向垂直位移的分析结果云图,如图4、5所示.

由图4、图5可以看出,微型桩墙支护设计的围岩横向水平位移最大值为6.99 mm,纵向垂直位移最大值为21.45 mm.锚网喷支护设计的围岩横向水平位移最大值为3.55 mm,纵向垂直位移最大值为8.73 mm.两种设计的对比分析结果见表2.

结果表明:两种支护方案下,最大位移均出现在洞口前方围岩处,边仰坡的实际位移变形极小,但围岩产生的横纵向位移差异较大.就位移最大值而言,锚网喷支护后的围岩横向水平位移较微型桩墙支护减少了49%,纵向垂直位移较微型桩墙支护设计减少了59%.对于产生的位移范围而言,锚网喷支护产生的横纵向位移范围远小于微型桩墙支护,横向水平方向大于1 mm的位移范围,微型桩墙支护单元占有率为2.7%,锚网喷支护后单元占有率仅为0.3%,降低了9倍; 纵向垂直方向大于3 mm的位移范围,微型桩墙支护单元占有率为21.8%,锚网喷支护后单元占有率为19.4%,降低了1.1倍.因此,锚网喷支护设计可以使围岩横纵向位移均得到有效控制,确保了围岩位移的稳定.

围岩的应力分布特征分析对稳定性起着至关重要的作用.应力场空间的分布特征和受力状态会由于隧道的开挖而改变,一些部位形成应力降低区和应力集中区,为达到新的平衡状态围岩将通过变形等方式进行应力调整.围岩的第一主应力云图如图6所示,两种设计的对比分析结果见表3.

通过模型计算结果的对比分析可知,微型桩墙支护设计模型隧道开挖引起的山体围岩最大拉应力为2.36 MPa,最大压应力为673.37 kPa; 锚网喷支护设计模型隧道开挖引起的山体围岩最大拉应力为1.91 MPa,最大压应力为673.24 kPa.满足安全施工要求.

两种设计方案对围岩产生的拉应力无明显变化,但锚网喷支护设计的最大拉应力较微型桩墙支护设计减少了19%,且在边坡坡脚处消失.值得注意的是最大拉应力均出现在右隧道洞口首次暗挖处.根据地勘资料可知,该模型最大应力出现部位均为花岗岩,花岗岩的屈服强度为100~250 MPa,所以两种方案各个部位的最大应力均小于花岗岩的屈服强度.

隧道衬砌是维护和支持隧道长期稳定的一种耐久性混凝土构件物.隧道衬砌受到围岩压力以及外部荷载的作用会产生内力与变形,稳定性也会受到影响,由于隧道为平面应变问题,本节将不考虑隧道纵向的内力与变形.通过对比两种设计方案下,二衬的内力与变形来分析隧道衬砌的稳定性.

隧道衬砌结构的受力特点可以由内力直接表现.两种洞口支护加固方案下隧道衬砌沿隧道开挖方向(Y轴负方向)弯矩的结果分析云图,如图7.

结果表明:衬砌基本呈受压状态.微型桩墙支护方案的衬砌最大弯矩为34.43 kN·m; 锚网喷支护方案下衬砌的最大弯矩为31.03 kN·m.锚网喷支护与微型桩墙支护相比,最大弯矩减少了9.9%,衬砌结构更加稳定.

隧道衬砌结构的横向位移能够直观的表明其稳定性.两种洞口支护设计方案下隧道二衬横向(X轴方向)位移的结果分析云图,如图8所示.

结果表明,微型桩墙支护设计的隧道二衬最大水平位移值为6.99 mm; 锚网喷支护设计的隧道二衬最大水平位移值为3.55 mm.两种方案下隧道衬砌均处于安全变形范围,未发生破损,但锚网喷支护方案比微型桩墙支护相比,最大水平位移值减少了49%.隧道衬砌横向水平位移得到有效控制,变形趋于收敛.

有限元强度折减法的基本原理是将岩土体强度参数进行折减,再作为一组新的参数进行输入,研究计算是否收敛,如果计算收敛说明土体仍处稳定状态,反复进行上述计算,直至不再收敛,此时岩土体将达到临界状态,稳定安全系数即为对应的F值[20].

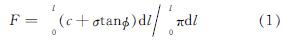

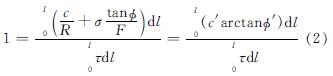

在Mohr-Coulomb准则下,边坡稳定极限平衡法的安全系数定义为滑移面上的抗剪强度和实际剪力之间的比值,即

将等式两面同时除以F,等式变为

式中:c'=c/F,φ'=arctan(tanφ/F),c为黏聚力; φ为内摩擦角; F为折减系数.

通过有限元强度折减法,MIDAS-GTS有限元软件对原设计与优化设计模型进行计算,安全系数的结果如图9所示.

由图可知,微型桩墙支护设计隧道洞口边坡的安全系数F值为5.156,锚网喷支护设计的隧道洞口边坡的安全系数F值为5.413.根据塑性区分布可知,在微型桩墙支护下,洞口段左右两侧边坡底部塑性区发育明显.锚网喷支护方案通过改善坡面坡度,并利用锚杆抑制了围岩松弛.洞口段塑性区得到了明显改善.通过对安全系数及塑性区的比较,结果表明微型桩墙支护设计与锚网喷支护设计的隧道边坡稳定性均不错,但是锚网喷支护设计方案的隧道边坡安全系数更高,更能抑制塑性区发育.因此,采用锚网喷支护更能确保施工安全.

通过现场反馈的实测数据能指导施工,及时调整支护参数,保证洞口仰坡的稳定,有效规避洞口坍塌以及山体滑坡等风险.根据模拟结果,现场实际工程采用锚网喷支护设计方案进行开挖.在施工过程中对洞口段地表沉降进行监测,通过对监测点变化规律进行分析以保证施工安全.

通常,隧道洞口地表沉降的趋势会有一定的变化规律.随着隧道的施工开挖,洞口地表开始产生变形,最大变形速率发生在隧道开挖掌子面到达检测点正下方时.若变形速率逐步减小,则说明隧道洞口趋于稳定; 反之,则隧道洞口将产生失稳,应及时采取措施以防止洞口坍塌,保证施工安全[21].现场采用直径25 mm长2 m外露0.5 m的钢筋在露头顶端焊接5 cm×5 cm的钢板对洞口段K7+280里程处地表沉降进行监测,监测点布置如图 10所示.分别选取开挖10 d、15 d、20 d、30 d及最终沉降值绘制地表沉降曲线图,如图 11所示.

由图可知,5个时间节点的地表沉降规律几乎保持一致.从总体趋势看,左洞沉降较大.这是由于地表沉降受地层不均匀分布、围岩性质不同、地表随机荷载、施工过程等因素的影响使得沉降曲线呈现不对称的双峰分布,沉降规律符合实际情况.地表沉降最大值位于左洞隧道轴线正上方,左、右洞隧道轴线处地表沉降值分别为27.2 mm和11.9 mm.沉降速率呈逐渐减小的趋势,表明隧道洞口趋于稳定,优化方案满足工程需要.

依托格鲁吉亚F3标5号公路隧道工程施工,利用数值模拟对比研究了微型桩墙支护方案和锚网喷支护方案下隧道围岩与衬砌的位移场、应力场特征变化.并结合现场监测数据来分析隧道的围岩稳定性,得出以下结论:

(1)采用锚网喷支护方案后,围岩纵横向位移及应力均得到了有效控制,相较于微型桩墙支护方案,围岩的水平位移、竖向位移分别减少了49%、59%.围岩最大拉应力减少了19%,且在边坡坡脚处消失.因此,锚网喷支护方案改善了隧道洞口段衬砌位移及内力,使衬砌更为安全;

(2)本工程围岩为重度花岗岩,边坡坡脚处塑性区发育明显.采用锚网喷支护方案时,边坡安全系数由5.156提升到5.413,增加了5%,表明采用锚网喷支护方案时,洞口边坡的稳定性较高;

(3)由洞口段地表沉降监测结果可知,隧道左、右洞轴线处地表沉降速率逐渐减小,表明隧道洞口趋于稳定,锚网喷方案在实际工程中应用效果可靠.该方案的成功实施为后续隧道建设提供一定的指导作用.