基金项目:国网天津市电力公司科技基金项目(KJ21-1-12)

第一作者:王 斌(1973—),硕士,高级工程师,主要从事电网材料腐蚀与防护研究.E-mail:70811326@qq.com 通信作者:陈洁静(1994—),博士生,主要从事混凝土耐久性研究.E-mail:xiajin@zju.edu.cn; chenjiejing@zju.edu.cn

(1.国网天津市电力公司,天津 300010; 2.国网天津市电力公司电力科学研究院,天津 300384; 3.浙江大学 建筑工程学院,浙江 杭州 310058; 4.桥梁结构健康与安全国家重点实验室,湖北 武汉 430034)

(1.State Grid Tianjin Electric Power Company, Tianjin 300010,China; 2.State Grid Tianjin Electric Power Research Institute, Tianjin 300384, China; 3.College of Civil Engineering and Architecture, Zhejiang University, Hangzhou 310058, China; 4.State Key Laboratory for Health and Safety of Bridge Structures, Wuhan 430034, China)

chloride ion; repaired concrete; reinforcement corrosion; micro-macro cell corrosion

DOI: 10.15986/j.1006-7930.2023.04.006

沿海地区服役的跨海大桥、港口和码头等混凝土结构,由氯盐侵入造成钢筋腐蚀,进而导致结构性能提早失效的现象十分普遍,长此以往给国民经济带来严重的经济损失[1].在氯离子环境下,混凝土内钢筋呈现纵向非均匀腐蚀特征,例如海水侵蚀下的桥墩、受荷状态下有裂缝的梁以及混凝土修补后的桥板等.通常认为,钢筋纵向非均匀腐蚀发生的原因包括腐蚀介质在钢筋表面非均匀分布以及结构本身的非均匀特性[2-3].

目前,针对由于钢筋腐蚀造成的混凝土保护层劣化现象,保护层替换是一种有效且普遍使用的修复技术.然而,在实际工程中,保护层替换后的混凝土构件往往会在短时间内再次发生微、宏电池腐蚀[4-5].这种修复后短期内的再腐蚀现象主要归咎于旧混凝土区域与新混凝土区域的氯化物含量、含氧量等环境的不同,使新的腐蚀电池生成[6].其中,宏电池腐蚀所占比例取决于修复区与旧混凝土区之间电化学环境,即二者之间不平衡的电化学电位,研究指出该电位差可达500 mV; 而微电池腐蚀的作用占比则与氯离子含量、电阻率等修复前旧混凝土区的本身性质相关,如图1所示.对于腐蚀再发生的位置,一般与所使用的修复材料、修复策略以及结构所处环境等因素有关[7].而对于腐蚀再发生的区域,沿修复后混凝土的纵向方向来看,大多是出现在修复界面处、修复区和与修复界面相邻的旧混凝土区中.其中,与修复界面相邻的旧混凝土区是腐蚀最严重的部位.Soleimani等通过数值模拟发现在距离旧混凝土区与修复混凝土区之间界面形成了环形的腐蚀阳极区[8].而对于混凝土修复界面的钢筋所处的状态目前仍未有定论,有学者认为此时钢筋处于活化状态[9],而也有学者提出钢筋处于钝化状态且钝化状态会从修复区域延伸至旧混凝土区域[10].

在工程应用中,基于电化学腐蚀原理的混凝土修复技术的优化方向主要集中在减缓阴阳极反应速度以及采用修补界面处理来阻止导电过程的发生上.对于修复方式的优化,Soleimani[8]研究发现腐蚀速率与修复区尺寸的关系不明显,而Lozinguez[11]提出全截面修复较采用部分截面修复方法的修复效果更优; 对于牺牲阳极布置方式的优化,Cheung[12]发现当牺牲电极放置在修复区时,修复界面附近旧混凝土区中钢筋的腐蚀电流密度会显著增加,因此应在旧混凝土区布置牺牲电极.

为描述混凝土修复后钢筋纵向非均匀腐蚀过程,本文提出了一个耦合物质传输—腐蚀区域界定—钢筋电化学腐蚀的多物理场模型.通过数值模拟,探讨了修补混凝土中钢筋的纵向微电池和宏电池的腐蚀机理与钢筋非均匀腐蚀的分布特征(沿钢筋纵向),同时分析了修复区长度和混凝土状态对修复效果的影响,本文旨在促进沿海基础设施建设与运维的发展.

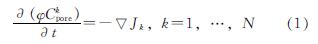

一般认为,混凝土内部固相和液相中带电粒子之间不发生化学反应,那么根据物质守恒方程,混凝土内部离子的浓度可描述为

式中:Ckpore,Jk分别为离子在混凝土孔隙液中的浓度(mol/m3)与通量(mol/(m2·s))(mol/(m2·s)); φ为混凝土孔隙率.

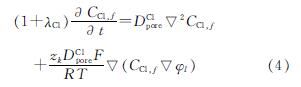

一般来说,饱和孔隙溶液中的离子输运过程基本上由三个因素控制:离子浓度差引起的扩散,压力梯度引起的对流和电场引起的迁移.因此,混凝土孔隙溶液中各种离子种类的通量,由Nernst-Planck方程给出[13-16].

式中:Dkpore为离子在混凝土孔隙液中的扩散系数(m2/s); F代表Faraday's 常数(C/mol); R为理想气体常数(J/(K·mol)); T为温度值(K); φl为混凝土孔隙液中的电势(V); φl为离子的化合价; zk为混凝土内离子对流速率,m/s;.

本文主要考虑了离子输运过程中的扩散与迁移作用机制,忽略对流对离子输运的影响,因此对于强对流作用的离子输运工程场景,本模型有一定的应用局限.联立式(1)与式(2),可得

将电解质溶液中离子传输方程应用于多孔材料时,需考虑氯离子的结合效应[13],采用Langmuir等温吸附的结合理论进行表征,因此在扩散及电迁移作用下混凝土内部氯离子浓度与混凝土内电势分布间的关系为[17]

式中:λCl=(αk)/(w(1+βkCCl,f)2)代表了氯离子结合效应的量,CCl,f代表自由氯离子含量(mol/m3),且w=0.3,αk=0.42,βk=0.8.

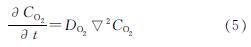

考虑到在混凝土中的氧气运输,一般情况下,氧气不会与其他物质发生反应,一般可用菲克第二定律来描述为

式中:DO2代表混凝土内氧气扩散系数(m2/s); 代表氧气在混凝土中的含量(mol/m3).

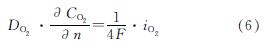

同时,在钢筋混凝土界面处,由氧气浓度的变化控制阴极反应的速率为

结合式(1)能够得到氧气浓度场控制方程:

式中:iL代表钢筋阴极区极限电流密度(μA/cm2); tn代表氧气的迁移数量; CO2代表氧气在阴极区的浓度(mol/m3); δ可取0.5 mm.

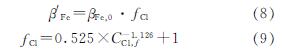

从理论上来说,塔菲尔斜率βFe只有在当金属表面达到主动溶解的条件时才存在,钢筋在钝化状态下的βFe无实质意义.一般认为,当钢筋表面氯离子含量较高且达到其脱钝阈值时,βFe会从无穷大逐渐下降直至保持为恒定值.鉴于此性质,Hussain[18]引入了阳极塔菲尔斜率影响系数(fCl),认为氯离子浓度对钢筋钝化膜的破坏可用fCl来表征,如式(8)所示.本文参考fCl的特性,基于已有文献中的数据[18-21],拟合出自由氯离子含量与fCl之间的关系方程,如式(9)所示.

阳极反应(Fe→Fe2++2e-)与阴极反应(O2+H2O+4e-→4OH-)共同存在于碱性环境中的钢筋-混凝土表面.根据Nernst方程,阳极和阴极反应的平衡势与产物(Fe2+)和反应物(O2)的活度有关,可以表示为

式中:PO2为溶液中氧气分压(Pa); PΘ为标准大气压(Pa); H为溶液pH值

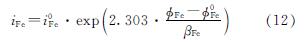

在腐蚀过程中,极化反应会导致平衡电位发生偏移.对于阳极反应,活化极化将促使电极电位发生变化,阳极反应电流密度iFe可表示为

对于阴极反应,可用活化极化和浓差极化来描述电流密度i0O2为

式中:i0Fe,i0O2,iL分别为阳阴极交换电流密度以及极限电流密度(A/m2),iL=(DO2zF)/(δtn)CO2; ηFe,ηO2分别为阳极、阴极过电位(V); φ0Fe,φ0O2分别为阳极、阴极平衡电位(V); βO2表示阴极反应的塔菲尔斜率.

修复后腐蚀电流密度icorr为微电池电流密度imic以及宏电池电流密度imac的总和,即

icorr=imic+imac (14)

钢筋表面可划分为阳极和阴极区,此时钢筋表面腐蚀电流密度可由表1表示.

根据法拉第定律,钢筋表面腐蚀深度与其腐蚀电流密度之间的关系可描述为

式中:X为钢筋钢筋表面一点坐标; n^→为钢筋表面法向向量; h为钢筋表面的腐蚀深度(mm); vFe=2; MFe=0.056 kg/mol; ρFe=7 860 kg/m3; n=4.

混凝土修复下钢筋纵向腐蚀的模型验证试验背景来自Ali的研究[6],在其试验中研究了在氯离子环境中采用不同修复方法对混凝土进行修复的效果.该试验中所用试件为1 000 mm×100 mm×200 mm的混凝土板,其中,保护层厚度为25 mm.试件中钢筋的直径为20 mm.该混凝土板修复区设置在构件中部,尺寸定为333 mm×333 mm×100 mm,具体布置以及几何信息如图2所示.在混凝土浇筑过程中加入了15%的NaCl溶液,使钢筋处于氯化物环境中.当混凝土完成修复后,为了加速其再腐蚀速率,同样将其浸泡在15%的NaCl溶液中.整个试验周期耗时15个月,测定了腐蚀电位、氯离子浓度和钢筋腐蚀速率等数据.

图2 模型示意图(Ali[6])

Fig.2 Schematic diagram of the model

图3是基于Ali的试验研究所建立的二维数值模型.一般地,当进行宏观尺度上的数值模拟时一般是将旧混凝土区与修复区的接壤处视作一个修复界面,因此,在二维几何上修复界面是线而非面[8].鉴于此,模型只对建成的旧混凝土区与修复区的赋予初始条件、边界条件、物质扩散系数以及电化学参数.表2、表3为关键输入参数[22-23].

根据Ali的试验结果,可以看出修复区与旧混凝土区之间存在着最小约35 mV,最大约103 mV的电位差.误差的存在可能由两方面因素造成,一是试验测试出的结果往往与钢筋-混凝土界面处的真实电位有所差异,特别是在宏电池腐蚀和局部腐蚀的情况下,活化和钝化区的腐蚀电位易受到它们之间的电偶耦合的影响,尤其在腐蚀初期,腐蚀电位会产生更显著的波动[24]; 二是试验环境因素以及材料因素导致电化学参数的选取具有离散性,而电化学参数的选取对混凝土中钢筋腐蚀进程的可测性能影响显著,因此大部分研究人员在进行电化学模型与试验与实际工程的验证工作时,二者的数值上有一定偏差[8],过去也有学者针对电化学参数对模拟结果的影响作过分析[23].虽然如此,但原则上由于水泥基材料电化学数值模型的局限性以及试验存在的随机误差,在相似的发展趋势下,相较于腐蚀电位测量的离散性,这种差异在可接受的幅度内.随时间的增加,腐蚀电位呈现出先增大后减小的趋势[6].相较于试验值,模拟结果的腐蚀电位波动较为平缓,如图4所示.

无论是试验结果还是模拟结果,相比于修复区的腐蚀电位,其他条件相同情况下旧混凝土区的腐蚀电位在负方向上的偏离更大.随着时间增加,两个区域之间的腐蚀电位差有所减小,最小约65 mV,最大约155 mV.出现这样的趋势是由于修复区与旧混凝土区之间的电化学环境差异随着物质输运的进行而逐渐缩小造成的.对于修复区与旧混凝土区的腐蚀电位与电位差曲线趋势,模型计算的结果与Ali试验结果相对吻合,验证了所建立的多场耦合模型用于分析混凝土修复后钢筋腐蚀行为的可行性.

基于所构建的多场耦合模型,本节对服役5 a利用保护层替换法进行再修复的混凝土板进行模拟,以分析构件内部钢筋的纵向非均匀腐蚀特征.图5为模型的几何尺寸示意图.对于修复区,在模型中此长度为200 mm,其内的初始氯离子浓度为0 mol/m3; 对于旧混凝土区,其长度为100 mm,保护层厚度为25 mm,且其内初始氯离子浓度沿保护层方向分布满足式(16).

式中:C0,Cs分别为混凝土初始、表面氯离子浓度(mol/m3); t为修复时构件被氯盐侵蚀的时间(s).

对于模型的混凝土表面氯离子,其浓度为65 mol/m3.模拟时间为1 800 d,其余参数均与2.2节一致.

修复混凝土构件钢筋再发生腐蚀的风险与其旧混凝土区域中氯离子浓度有关,氯离子浓度越高的旧混凝土区,修复区内钢筋再腐蚀的概率与速率越大.该这个现象是由修复区与旧混凝土区之间电化学差异所造成的,而氯离子浓度为钢筋所处电化学环境特征的重要指标之一.Pruckner指出,修复后的混凝土区域通常不含氯化物,而旧混凝土区内含氯化物,因此,修复区中钢筋的腐蚀电位可能比旧混凝土区中钢筋的腐蚀电位高得多[25].为了得到沿钢筋纵向的修复区、修复界面和旧混凝土区中氯离子含量情况,除修复界面外,均选择属区中点作为代表性点,如图6所示.可以看出,随着时间的递增,各个区域点的氯离子浓度有所提高,且增长速率在不同区域呈现出较大的差别.随着时间的推移,新老混凝土区之间氯离子浓度的差异逐渐减小,这个趋势可以归因于修复区内外的氯离子浓差大于旧混凝土区,促使氯离子扩散速率增加.

图7为混凝土修复下各个区域的钢筋腐蚀电位.对于修复下的初始腐蚀电位,修复区与旧混凝土区有一定的差别,两个区域的差值可达到110 mV.修复区和旧混凝土区腐蚀电位差随时间延长而减小,而到1 800 d时两个区域间的电位差已经降低到2 mV.电位差的巨大降幅是由于在浓差驱动下旧混凝土区与修复区之间的氯离子浓度差异性进一步降低.而随着时间的增长,两个区域间钢筋表面腐蚀电位的电位差降幅更为明显,说明了虽然钢筋腐蚀程度增大,但腐蚀速率亦呈现减缓趋势.

图8(a)展示了当t=0 d时沿钢筋纵向腐蚀电流密度的发展趋势.可以看出,最大腐蚀电流密度出现在距离界面8 mm的旧混凝土区内,其值达到4.25 μA/cm2,该现象也被称为阳极环效应.在Barkey的研究中也观察到了界面附近的腐蚀电流密度的骤升[26],进一步的,Soleimani通过数值模拟指出腐蚀密度增加的区域距离界面区2~5 cm.这是因为修复区中的钢筋(阴极)和旧混凝土区中的钢筋(阳极)之间形成了宏电池腐蚀从而增加了阳极腐蚀速率,对于靠近界面的区域阳极环效应效应尤为明显.沿钢筋纵向方向看,修复后在0~100 mm的旧混凝土区的腐蚀电流密度表现为典型的非均匀分布.在纵向方向,钢筋可划分为由微电池主导的腐蚀区域(0~80 mm区域)、由宏电池主导的腐蚀区域(80~100 mm)以及由微电池主导的修复区(100~300 mm区域)三个区域.

图8(b)为修复后钢筋表面点l=90 mm处的腐蚀电流密度的发展趋势.可以看出,腐蚀电流密度先降低后趋于稳定.尤其在前100 d内,无论是微电池腐蚀电流密度还是宏电池腐蚀电流密度,均发生大幅度地下降.根据图8(a)的区域划分,当t=0 d时,在l=90 mm处可被界定为宏电池主导的腐蚀区域,而此时该点的宏电池腐蚀电流密度占比大约为56%.随着时间增长,在该点的宏电池腐蚀电流密度逐渐下降,而微电池腐蚀电流密度有所上升,在约为100 d后,微电池腐蚀效用占比超过宏电池腐蚀效用占比.1 800 d后,微电池腐蚀作用完全占据主导.

图9为混凝土修复下钢筋腐蚀深度与形态分布图.在修复后的任意时刻,沿钢筋纵向总是呈现出非均匀的腐蚀特征,且其中腐蚀最深的部位皆出现在距离修复界面34~42 mm处的旧混凝土区内,该区域初始时刻钢筋腐蚀深度为0,而到1 800 d后腐蚀深度最大可超过110 um.此外,从腐蚀深度随时间变化曲线可看出相同的时间梯度下腐蚀深度的增长幅度较为平均.

本节以混凝土修复前所经历的氯离子侵蚀时间以及修复区设定长度作为参数,研究混凝土修复下旧混凝土内初始状态以及修复区长度对钢筋腐蚀速率的影响.参数化分析中给出的腐蚀发展趋势与规律,可以作为对试验或实际工程的补充与参考,特别是对于具有相似条件的工况.图 10(a)展示了旧混凝土区内钢筋表面初始氯离子浓度随时间而逐渐增加的情况,表明旧混凝土区在修复初始时刻的腐蚀风险更高,而修复区与旧混凝土两个区域之间的电化学环境差异也将扩大.在实际工程中,修复前的旧混凝土区内氯离子浓度等状态特征会显著影响修复效果,这就意味着若在混凝土构件不同的服役时刻上进行修复处理,得到的修复效果是迥异的.根据图 10(b)中的t=0时腐蚀电流密度峰值的曲线,不难发现修复前氯盐侵蚀时间越长,再腐蚀时钢筋的腐蚀电流密度峰值将越大,而宏电池腐蚀对腐蚀电流密度峰值增量的作用占比一直维持在65%,并不受氯盐侵蚀时间的影响.

关于修复区域尺寸大小(50~250 mm)对电流密度峰值影响的情况如图 11所示.可见,随着修复区长度的递增,无论是腐蚀电流密度峰值还是宏电池腐蚀电流密度均有上升趋势.而微电池腐蚀电流密度发展与前两者相反,其具体表现为:随着修复区长度的增大,其峰值出现轻微下降.这说明,随着修复区长度的增加,钢筋腐蚀由宏电池腐蚀主导的同时,微电池腐蚀被抑制.在一定的阴极面积与阳极面积之比的范围内,该面积之比与钢筋腐蚀速率成正相关关系.阳、阴极面积比越小,腐蚀速率相对越快,因此理论上修复区长度不宜过长.模拟结果对今后工程上的修复混凝土腐蚀规律发展具有一定的指导作用,但精准的修复区长度的确定还需结合结构实际构造(旧混凝土区尺寸)、服役环境.

(1)随着时间的推移,混凝土修复下旧混凝土区与修复区间氯离子浓度的差异会逐渐减小,同时两个区域之间的钢筋表面腐蚀电位的电位差显著降低;

(2)混凝土修复后腐蚀出现在靠近修复界面的旧混凝土区中,且修复界面存在阳极环效应,其腐蚀电流密度最大值可达4.25 μA/cm2

(3)修复前旧混凝土区内的氯离子浓度会显著影响腐蚀速率,修复前氯盐侵蚀时间越长,再腐蚀时钢筋的腐蚀电流密度峰值更大;

(4)修复区长度对混凝土修复效果存在显著影响,随修复长度增大,宏电池腐蚀作用占主导地位而微电池腐蚀作用受到抑制.