基金项目:浙江省自然科学基金资助项目(LZ20E080003,LR21E080002,LQ22E080017),国家自然科学基金资助项目(51978620,52208294)

第一作者:董 征(1994—),女,博士,讲师,主要研究方向为混凝土结构耐久性、腐蚀与防护.E-mail:zdong@zjut.edu.cn 通信作者:付传清(1982—),男,博士,教授,主要研究方向为混凝土结构耐久性.E-mail:chqfu@zjut.edu.cn

(College of Civil Engineering, Zhejiang University of Technology, Hangzhou 310023, China)

reinforced concrete; non-uniform corrosion; corrosion-induced cracking; cracking mode

DOI: 10.15986/j.1006-7930.2023.04.016

钢筋锈蚀导致混凝土开裂是影响混凝土结构耐久性的主要原因之一,非均匀锈蚀是钢筋自然锈蚀中的主要形式.由于有害物质的侵蚀和氧气、水的传输在自然环境下都是由外到内的过程,因此钢筋会在靠近保护层一侧率先脱钝锈蚀.相比于均匀锈蚀,非均匀锈蚀一方面形成宏电池可加速钢筋锈蚀,另一方面则会导致保护层的开裂更为迅速和严重[1-3].因此,研究非均匀锈蚀下混凝土的开裂模式对混凝土结构寿命的预测具有重要意义.

研究混凝土结构锈胀开裂的主要方法有理论分析、试验研究、数值模拟[2-5].其中,试验研究中诱导钢筋锈蚀的方法主要包括自然环境锈蚀[6]、人工环境加速锈蚀[7]、通电加速锈蚀[8-12].针对混凝土结构中钢筋锈层分布以及锈胀开裂的预测,人工环境加速锈蚀下的钢筋呈现非均匀锈蚀,其锈层分布可用高斯函数描述,与自然环境锈蚀吻合.然而,自然环境锈蚀与人工环境加速锈蚀所需的试验周期均较长,通电加速锈蚀成为研究混凝土结构锈胀开裂的主要方法之一.Fu等[13]利用一种基于内置电极法的加速非均匀锈蚀方法对混凝土试块进行试验,可得到与自然环境下高斯型锈层分布相符合的钢筋锈层分布,同时大大缩短了试验周期.针对锈胀开裂的数值计算,现有的非均匀锈蚀有限元模型模拟膨胀力的方法包括热模拟、荷载模拟、径向位移模拟[14-15].然而,大多数的模型都是采用半椭圆形模型模拟锈层的非均匀分布[16-17],与实际非均匀锈蚀钢筋的锈层分布有一定差别.

由此,本文以高斯分布的径向位移模拟锈层的非均匀分布.以此模型探究锈蚀方式、钢筋位置、钢筋直径、保护层厚度对应变场分布、开裂模式的影响.另外,采用内置电极法的通电加速锈蚀试验,利用应变仪采集锈蚀过程中的应变变化,以试验数据验证模型的准确性.

在基于内置电极法的钢筋非均匀锈蚀通电试验中,导致钢筋非均匀锈蚀的原因就是电流的非均匀分布,因此,锈层的分布应与电流密度的分布一致.为了得到电流在钢筋表面的分布,利用COMSOL对于钢筋非均匀锈蚀通电试验进行了模拟.本文主要针对基于钢筋横截面非均匀锈蚀的锈胀开裂开展研究,暂未考虑沿钢筋长度方向的纵向非均匀性,采用二维模型[5,18].

如图1所示,设置混凝土尺寸为150 mm×150 mm×75 mm,保护层厚度为30 mm.钢筋和钢丝为两个电极,钢筋的平均电流密度设置为3×10-6 A/mm2.模型中混凝土电导率数值由试验实测得到,为0.014 39 S/m,本文暂未考虑混凝土材料的非均质性.在通电锈蚀的过程中,主要控制锈层分布的因素是不锈钢丝与钢筋的截面积之比、不锈钢丝和钢筋的净距.当不锈钢丝与钢筋的相对位置不同时,钢筋锈层仍符合高斯分布,但锈层分布具体数值发生改变[13].基于作者已有研究,不锈钢丝与钢筋截面积之比及净距愈小,钢筋通电锈层分布与自然锈蚀下锈层分布愈相近,且不锈钢丝本身对开裂的影响可忽略不计[13].根据已有试验及模拟结果[13],在本文中钢丝和钢筋净距设定为8 mm,钢丝的直径固定为0.8 mm,因此在模拟过程中,主要考虑钢筋直径对于电流分布的影响,设置钢筋直径d为8 mm、12 mm、16 mm、24 mm、32 mm.

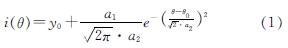

以d=16 mm的计算结果为例,如图1所示,流线越密集,表示电流密度越大.钢筋表面最靠近钢丝的位置电流密度最大,随着钢筋表面各点与钢丝距离增加,电流密度逐渐降低.将各种情况的钢筋表面的电流密度分布导出,并用高斯函数拟合,具有很好的拟合度,见式(1).

式中:y0为均匀系数,反映圆周方向上均匀分布的电流密度; a1为非均匀系数,反映非均匀分布的电流密度的总和; a2为扩展系数,反映高斯分布图像的缓陡程度; θ0表示函数的对称轴位置,θ0=0.钢筋圆心与钢丝圆心连线的角度θ定义为θ=0轴,顺时针旋转为负值,逆时针旋转为正值,因此θ的取值范围为[-π,π).最终得到电流密度分布拟合曲线(图2),并得到参数与钢筋直径的关系图(图3).其关系式可由幂函数较好地拟合,拟合函数如表1所示.

图2 钢筋不同角度位置电流密度分布拟合图

Fig.2 Fitting diagram of current density distribution at different angles of steel bar

如图3与表1所示,y0和a2随着钢筋直径的增大而减小,a1随着钢筋直径的增大而增大.通电锈蚀过程中,锈层厚度分布与电流密度分布一致.因此在相同的锈蚀率下,随着钢筋直径的增加,锈层厚度分布越陡峭,均匀部分减小,非均匀部分增大,最大锈层厚度增大.

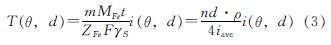

锈层厚度分布与电流密度分布一致呈现高斯分布,根据Faraday定律公式和锈蚀产物几何关系公式可得

最终可得到锈层厚度分布函数为公式(3)所示,也符合高斯分布,与锈蚀试验得到的锈层厚度分布规律一致[19]:

式中:n为铁锈体积膨胀系数,取2; MFe为铁的摩尔质量,取56 g/mol; t为通电时间(s); ZFe为铁的化合价,取2; F为法拉第常数,取96 485 C/mol; γs为钢筋密度,取7.85×106 g/m3; iave为钢筋表面平均电流密度; d为钢筋初始直径; ρ为钢筋的锈蚀率.

为了探究钢筋混凝土在锈蚀过程中开裂模式,利用ABAQUS模拟锈胀开裂过程.模型采用塑性损伤模型来模拟混凝土锈胀开裂,单元类型为CPS4R,用等直径的空洞来代替钢筋位置,由于钢筋周围的应力应变较为集中,所以,对钢筋周围的网格划分适当加密,采用钢筋的径向扩张位移来模拟锈蚀产物的堆积.模型中的混凝土材料参数见表2[20].

图4为本文试验测得混凝土受拉本构模型,受拉时应变发展很快,极限拉应力为2.01 MPa.如图5所示,当混凝土达到极限拉应力时,混凝土开始产生应变,但是应力没有马上急剧减少,应变没有急剧增加,当塑性拉应变达到150微应变时,开始急剧增加,应力急剧减少.因此本模型开裂的判定准则为极限拉应变准则,极限拉应变为150微应变.

根据锈层厚度的分布函数,可得到钢筋圆周方向的径向位移函数为:

式(4)为钢筋位于中部位置锈层厚度的分布曲线、式(5)为钢筋位于角部位置锈层厚度的分布曲线.式中,i(θ)为电流密度的分布函数.

模型中混凝土尺寸为150 mm×150 mm.钢筋位于试件中轴位置,钢筋直径16 mm,混凝土保护层厚度30 mm.根据试验数值,钢筋表面平均电流密度取为300 μA/cm2,该通电电流密度能在不显著影响钢筋混凝土锈胀行为的情况下大大缩短试验所需时间[21].根据公式(4)设置径向位移,最终锈蚀率为0.270%.在混凝土未开裂前,随着钢筋锈蚀率的增加,其应变分布数值增大,但是规律一致,因此以钢锈蚀率为ρ=0.014%时为例,混凝土的环向应变云图如图6所示.分别提取距离钢筋表面的径向位移s在30 mm内的混凝土环向应变在圆周方向上的分布,绘于图7.

由图中可以看出,随着s增大,应变值总体呈减小趋势,但在θ=0附近即靠近保护层一侧,混凝土应变随着s的增大先减小后在混凝土表面附近又增大,在s=30 mm处达到最大.在靠近钢筋表面附近,相同s的圆周上应变的极大值点位于θ=±5π/12以及θ=-π处; 在靠近混凝土表面附近,相同s的圆周上应变的极大值点位于θ=0处.图中的曲线分别是不同s下应变极大值点的连线.

图7 开裂前(ρ=0.014%)距离钢筋表面30 mm内的混凝土环向应变分布图

Fig.7 Circumferential strain distribution of concrete within 30 mm from the surface of steel bar in the case of ρ=0.014%

图8为当ρ=0.270%时,大于150微应变的应变云图,根据极限拉应变准则判定开裂,图8所示的应变位置即裂缝位置.可见,混凝土的主要裂缝有3种:竖直方向靠近保护层一侧的L1裂缝,远离保护层的L3裂缝,水平方向的L2裂缝,L1,L2,L3裂缝所在角度分别为0,±5π/12,-π.图7中应变极大值点的连线位置与图8所示裂缝的位置相吻合.

将不同锈蚀率下混凝土的应变云图绘于图9,可见,当ρ=0.027%时,L2裂缝从钢筋表面周围出现; 当ρ=0.051%时,L2裂缝从内向外延伸,L1裂缝从保护层表面出现; 当ρ=0.065%时,L1裂缝已经贯穿保护层,L3裂缝从钢筋表面周围出现.可以看出L1裂缝是由保护层表面开始开裂,然后向混凝土内部扩展(裂缝开展方向记为表3中的外部-内部); L2裂缝和L3裂缝则相反,裂缝由钢筋表面向外侧扩展(裂缝开展方向记为表3中的内部-外部).根据裂缝开展过程,提取裂缝起裂和终裂位置单元的应变变化数据,并根据极限拉应变准则,得到裂缝的开裂临界锈蚀率,总结其开裂模式如表3所示.

图9 不同锈蚀率下的裂缝开展过程

Fig.9 Propagation of corrosion-induced cracks of concrete under different corrosion rates

为了验证有限元模型,采用了内置电极法通电加速试验模拟钢筋的非均匀锈蚀,在靠近钢筋位置预置不锈钢丝,在通电过程中,电源的正极连接钢筋,电源负极连接不锈钢丝,可以通过改变钢丝和钢筋的间距改变钢筋锈层的分布,该方法的通电效率更高.

混凝土试件的配比如表4所示.水泥采用P·O 42.5水泥; 细骨料为河砂,细度模数为3.0; 粗骨料为破碎石灰岩,5~16 mm连续级配.钢筋采用HPB300、直径为16 mm的光圆钢筋,不锈钢丝直径为0.8 mm.混凝土试件的尺寸为150 mm×150 mm×75 mm,混凝土试件的中部布置1根钢筋,保护层厚度为30 mm,非均匀锈蚀的试块在钢筋正对保护层方向距离钢筋表面8 mm处预置不锈钢丝(图 10),与有限元模拟中模型尺寸一致.标准混凝土试块养护28 d后的抗压强度为17.9 MPa.试验装置由通电加速锈蚀系统和应变自动采集系统组成,试件放置于室内(温度约为20℃),应变片位于试件底面,如图 10所示.

表4 混凝土配合比(kg/m3)

Tab.4 Mix proportion of concrete(kg/m3)

图 11是应变片处混凝土应变值和有限元相应单元的预测曲线.可见,随着锈蚀率的增加,应变值不断增加,混凝土应变试验值与有限元理论值吻合良好.基于本文所提出模型计算得到的混凝土保护层表面开裂临界锈蚀率为0.051%,试验值为0.054%,误差率为6.9%,吻合良好.由此,本文所提出的混凝土锈裂模型能够较好地计算在非均匀锈蚀过程中混凝土的应变及锈胀开裂时间.

为了探究锈蚀类型、钢筋直径、钢筋位置、保护层厚度对于混凝土开裂模式的影响,将混凝土试件编号为:Z/D-U/N-d8-c20.其中Z/D中的Z钢筋位于试件中轴位置、D位于角部位置; U/N:U为均匀锈蚀、N为非均匀锈蚀; d8:钢筋直径(8 mm,12 mm,16 mm,24 mm,32 mm); c20:保护层厚度(20 mm,30mm,40 mm,50 mm).

针对锈蚀方式对于开裂模式的影响,设置径向位移公式中的i(θ,d)=iave,最终锈蚀率为0.270%,得到Z-U-d16-c30试件的结果,ρ=0.014%时距离钢筋表面30 mm内混凝土环的应变分布如图 12所示,裂缝形态如图 13所示,开裂模式如表5所示.

图 12 开裂前(ρ=0.014%)距离钢筋表面距离30 mm内的混凝土环向应变分布图

Fig.12 Strain of concrete within 30 mm from the surface of steel bar in the case of ρ=0.014%

如图 12所示,当s增大时,应变的变化规律与非均匀锈蚀时一致,在靠近钢筋表面附近,应变的极大值点连线位于θ=±π/2、θ=-π以及θ=0处,在靠近混凝土表面附近,应变的极大值点连线位于θ=0处,曲线与图 13所示的裂缝位置相吻合.

如表5所示,均匀锈蚀下L1裂缝是从钢筋表面先开裂,延伸到保护层表面,与非均匀锈蚀下相反.L1裂缝的位置相同,贯穿保护层的临界锈蚀率相差不大,均匀锈蚀下裂缝延伸较慢,非均匀锈蚀下裂缝从开始出现到贯穿保护层发展极快.均匀锈蚀下L2裂缝所在角度为±π/2,裂缝开展过程与非均匀锈蚀下一致,但是非均匀锈蚀下L2裂缝开裂的更早.均匀锈蚀下L3裂缝位置与开展过程与非均匀锈蚀下一致,但是均匀锈蚀下L3裂缝开裂的更早.

为了探究锈蚀方式对于开裂模式的影响,根据公式(5)设置径向位移,最终锈蚀率为0.540%,得到D-N-d16-c30试件的结果,ρ=0.014%时距离钢筋表面30 mm内混凝土环的应变分布如图 14所示,裂缝形态如图 15所示,开裂模式如表6所示.

图 14 开裂前(ρ=0.014%)距离钢筋表面距离30 mm内的混凝土环向应变分布图

Fig.14 Strain of concrete within 30 mm from the surface of steel bar in the case of ρ=0.014%

如图 14所示,当s增大时,应变的变化规律与钢筋位于中部位置非均匀锈蚀时一致,在靠近钢筋表面附近,应变的极大值点连线位于θ=-5π/12、θ=π/4以及θ=11π/12处,在靠近混凝土表面附近,应变的极大值点连线位于θ=0以及θ=π/2处,曲线位置与图 15所示的裂缝位置相吻合.

对比图7、图 12、图 14的环向应变分布图,发现不同试块下钢筋周围混凝土的应变在径向上的分布规律是一致的,即随着跟钢筋表面径向距离的增大,环向应变大体呈现减小趋势,但是靠近保护层一侧的环向应变在减少到一定程度后在混凝土表面附近又逐渐增大.然而,其在圆周方向上的分布规律是不完一致的,在靠近钢筋表面的圆周上,应变极大值点的连线位置各不相同; 但在靠近混凝土表面的圆周上,应变极大值点的连线位置均位于钢筋和混凝土表面最小距离的路径上.这些极大值点的径向连线的位置就是混凝土开裂后裂缝出现的位置,因此也说明了不同试块下其裂缝位置也是不同的.

如图 14和表6所示,钢筋位于角部位置时,3条主裂缝关于θ=π/4轴对称,且起锈时间提前了,这是因为位于角部时,径向位移是两个高斯函数的叠加,最大径向位移位于θ=π/4处.钢筋位于角部位置时L1裂缝贯穿保护层的临界锈蚀率大于中部位置,但是在通电锈蚀过程中,钢筋位于角部位置时锈蚀率增加速度是中部位置的2倍,钢筋位于中部位置时裂缝的开裂时间是远远早于角部位置.

为了探究锈蚀方式对于开裂模式的影响,根据公式(5)设置径向位移,最终锈蚀率为0.27%,最终得到Z-N-d(8、12、16、24、32)-c30试件的结果,开裂模式列于表7,裂缝开裂临界锈蚀率与直径的关系如图 16所示.

如表7所示,钢筋直径的增加,L1裂缝都是位于θ=0处,裂缝都是从钢筋表面开裂延伸到保护层表面(除d=8时,钢筋表面先开裂,保护层表面再开裂,然后两个方向延伸贯穿保护层).L2裂缝的位置所在角度随着直径的增加而越靠近θ=0轴,裂缝开展都是由内部向外部开展.L3裂缝都是位于θ=-π处,裂缝开展都是由内部向外部开展.如图 16所示,L1裂缝、L2裂缝的开裂临界锈蚀率随着直径的增加而降低,L3裂缝的开裂临界锈蚀率随着直径的增加而增加.这是由于根据径向位移公式L(θ,d)显示,钢筋直径越大,位移非均匀部分越大,均匀部分越小,最大径向位移越大,分布越集中.

为了探究锈蚀方式对于开裂模式的影响,根据公式(5)设置径向位移,最终锈蚀率为0.27%,最后得到Z-N-d16-c(20、30、40、50)试件的结果,开裂模式如表8所示,裂缝开裂临界锈蚀率与直径的关系如图 17所示.

图 17 临界锈蚀率与保护层厚度的关系图

Fig.17 Relationship between critical corrosion rate and thickness of concrete coverr

如表8所示,保护层厚度的增加对于裂缝位置、裂缝开展过程没有影响,当保护层厚度大于60 mm时,L1裂缝将不再开裂(在表中由“/”表示),L2裂缝贯穿了混凝土水平方向.由图 17可见,随着保护层厚度的增加,L1裂缝、L3裂缝的开裂临界锈蚀率增加,保护层厚度对于L2裂缝的开裂临界锈蚀率影响不大.这是因为钢筋直径一定时,钢筋径向位移相同,保护层厚度越大,对L1裂缝的发展抑制越强,而L2裂缝方向的混凝土厚度不变.

本文提出了一个模拟内置电极法加速非均匀锈蚀过程中钢筋表面电流分布的有限元模型以及钢筋混凝土锈胀开裂的有限元模型,并通过锈蚀试验进行了验证.基于本研究,可以得到以下结论:

(1)钢筋锈蚀产物的锈层分布与电流密度分布一致.随着钢筋直径的增加,钢筋锈蚀产物的锈层在钢筋表面的分布越集中,非均匀部分增加,均匀部分减少,最大锈层厚度增加.基于钢筋非均匀加速锈蚀模型的保护层胀裂临界锈蚀率计算值与试验值误差小于10%,表明根据钢筋表面电流分布的有限元模型能对非均匀加速锈蚀下钢筋混凝土锈胀开裂行为进行较为准确的预测;

(2)在钢筋锈蚀过程中,混凝土未开裂时,不同试块中钢筋周围混凝土的应变场在径向上的分布规律一致; 在圆周方向上的分布规律不一致.混凝土开裂前应变场的分布规律与开裂后裂缝的位置和发展规律具有相关性;

(3)均匀与非均匀锈蚀,保护层裂缝开展方向相反; 钢筋位于试块中部位置保护层一侧裂缝的开裂临界锈蚀率大于角部位置;

(4)非均匀锈蚀时,保护层一侧裂缝的开裂临界锈蚀率随着钢筋直径的增大而减小,随着保护层厚度的增大而增大; 水平方向裂缝的开裂临界锈蚀率随着钢筋直径的增大而减小; 保护层厚度的变化并不影响所有裂缝的位置、开展方向以及水平方向裂缝的开裂临界锈蚀率.