基金项目:国家重点研发计划资助(2021YFB3704402)

第一作者:郭瑞(1994—),男,在读博士,研究方向为土木工程纤维增强树脂复合材料混杂与耐久性.E-mail:guorui080539@163.com 通信作者:咸贵军(1972—),男,博士,教授,研究方向为纤维增强树脂复合材料与结构性能.E-mail:gixian@hit.edu.cn

(1.哈尔滨工业大学 结构工程灾变与控制教育部重点实验室,黑龙江 哈尔滨 150090; 2.哈尔滨工业大学 土木工程学院,黑龙江 哈尔滨 150090; 3.中国石油化工集团有限公司 胜利石油管理局科技处,山东 东营 257000)

(1.Key Lab of Structures Dynamic Behavior and Control, Harbin Institute of Technology, Ministry of Education, Harbin 150090, China; 2.School of Civil Engineering, Harbin Institute of Technology, Harbin 150090, China; 3.Shengli Oilfield Company, China Petroleum & Chemical Corporation(SINOPEC), Shandong Dongying 257100, China)

carbon-glass fiber hybrid rod; mechanical performance; hygrothermal durability; fatigue performance; hybrid effect

DOI: 10.15986/j.1006-7930.2022.02.003

纤维增强树脂基复合材料(FRP)相较于传统建筑结构材料具有轻质、高强、耐疲劳与耐腐蚀等优异性能,在土木工程领域已得到了广泛的关注与应用[1].其中,FRP筋替换传统的钢筋用于增强混凝土结构; FRP板材用于修补加固受损的钢与混凝土结构[2]; FRP索替换钢索用于桥梁结构[3].FRP复合材料在工程中的应用,可以有效的提升结构材料抗腐蚀、疲劳破坏等性能,从而提升结构的服役可靠度、服役安全与服役寿命,带来可观的社会与经济效益.

碳纤维增强树脂基复合材料(CFRP)具有优异的耐腐蚀、耐疲劳等性能,但成本较高,玻璃纤维增强树脂基复合材料(GFRP)成本低廉,但模量、强度较低且耐疲劳性能较差,断裂伸长率较高.通过碳纤维与玻璃纤维混杂制备复合材料,可以发挥碳纤维与玻璃纤维的性能与成本优势,制备更高性价比的混杂纤维复合材料制品.相对单一纤维复合材料而言,混杂复合材料内部纤维的断裂破坏过程发生变化[4].高延性玻璃纤维能有效地降低由于低延性碳纤维断裂而形成的应力集中; 同时,由于玻璃纤维的桥联作用,阻滞了碳纤维断裂簇的形成,提高了碳纤维断裂簇的临界尺寸[5].基于上述两个作用,提升了混杂复合材料内低延性纤维的断裂伸长率[6],如混杂复合材料较单一碳纤维复合材料的断裂伸长率提高10%~40%[7],其强度与断裂伸长率均实现正混杂效应.

碳-玻璃纤维复合材料的正混杂效应取决于碳纤维的分散度、相对含量、混杂方式、纤维性能与纤维/树脂界面粘结性能等材料参数[4].纤维混杂得越均匀,混杂效应越显著,如纤维束随机混杂对复合材料正混杂效应的提升远高于层间混杂[4]; 对于层间混杂,对碳纤维层薄层化处理降低碳纤维的含量后,碳纤维在受力过程中会逐步断裂或从树脂中拔出,其最终断裂伸长率远大于纯碳纤维复合材料,混杂复合材料表现出假延性[6-7]; 综上可知,增加低延性纤维的离散度,可以显著提高低延性纤维的断裂伸长率,进而提高杆体的正混杂效应[5].

虽然FRP复合材料具备优异的耐湿热老化与疲劳性能,但在长期服役过程中,恶劣的土木工程服役环境与荷载会造成FRP性能的显著退化.在湿热、pH、紫外、冻融与疲劳荷载老化等腐蚀环境下,FRP会产生树脂基体开裂、界面脱粘与纤维断裂等损伤,严重影响结构的服役可靠度、寿命与安全.其中,湿热与疲劳荷载是土木工程结构中最常见的两种服役环境.为了确保FRP在上述环境下具有可靠的服役性能,有必要研究FRP在湿热与疲劳荷载作用下的长期耐久性能,获得FRP力学性能演化规律与机理.

湿热环境所导致的FRP性能退化与材料的水吸收有着密切关系[8-9],较高的吸水量会导致更严重的性能退化[10].在潮湿环境下老化15 a后,FRP杆体的层间剪切性能退化10%~50%[11].在蒸馏水环境中浸泡1a后,FRP杆的纤维/树脂界面强度退化了25%~43%.在过去的几十年里,许多学者对CFRP和GFRP的疲劳性能进行了研究[12-14],结果表明,CFRP比GFRP具有优异的疲劳性能.FRP的疲劳寿命高度依赖于材料系统本身,如纤维、树脂基体性能、铺层顺序和制造过程中的残余应力[15-17].纵然广大学者对FRP湿热老化与疲劳性能有系统而深入的研究,但是针对碳-玻璃纤维混杂复合材料杆体的湿热老化与疲劳性能的研究较少,因此,有必要系统地开展混杂杆体在湿热与疲劳荷载作用下的长期服役性能研究.

实际工程应用过程中,低的碳纤维含量尽管有利于实现正混杂效应,但复合材料的性能更偏向于玻璃纤维复合材料,并不能够满足对材料耐腐蚀、疲劳、模量性能的要求.本文以碳-玻璃纤维混杂拉挤杆为对象,研究碳纤维与玻璃纤维比(2︰3)在较高情况下,纤维分布情况对拉挤杆静力性能、湿热耐久性能与疲劳性能的影响.研究将有利于碳-玻璃纤维混杂复合材料的设计、制备与应用.

本研究使用的原材料是通过拉挤技术生产的单向碳-玻璃纤维增强环氧树脂复合材料杆体.包括碳纤维杆(CFRP rod),随机混杂杆体(UDH rod),皮芯包覆杆(GCH rod).对于UDH杆,碳纤维束随机地分散在玻璃纤维中,而GCH杆的皮层为玻璃纤维增强环氧树脂,芯层为碳纤维增强环氧树脂,相应的混杂杆体的横截面结构组成如图1所示.

在本研究中,所有杆体纤维体积分数约为70%,其中混杂杆体碳/玻璃纤维体积分数比为2:3.12 K的碳纤维(上海石化,上海,中国)、玻璃纤维(OC 2400tex,Owens corning, America)和双酚A型环氧树(AirstoneTM 1122E,蓝立方化学公司,浙江,中国)用于混杂杆体的生产,纤维与树脂的力学性能列于表1中.

纤维增强复合材料具有较高的纵向拉伸性能,但其横向抗剪切与抗压性能差,造成纤维增强复合材料杆体锚固困难[18].为了解决现有锚固系统存在的锚固效率低、锚具内部应力分布不均匀、耐疲劳性能差等问题,为碳-玻璃纤维混杂杆体的力学测试提供一种可靠的锚固系统.本文发展了一种挤压-粘结型锚固系统,该锚固系统由碳-玻璃混杂杆体、钢套筒与钢楔块组成,如图2所示.

钢套筒与钢楔块的长度设置为150 mm,钢套筒的内部锥度为1°.为了降低锚具端部杆体所受的剪应力,钢套筒与钢楔块之间设置0.1°的锥度差.钢楔块设置为等分的三瓣,内孔为圆形通孔,并且钢楔块内孔直径小于与杆体直径0.3 mm,为了抵消杆体受压变形所造成的直径减小,使得在受力过程中钢楔块内孔与杆体表面贴合得更加紧密.该锚固系统的操作具体包括以下步骤:(1)将杆体两个锚固端用砂纸打磨,进行粗糙处理,同时对锚固钢管的内孔进行除锈,用无水乙醇将打磨后的FRP杆体、锚固钢管内孔擦拭干净;(2)将杆体放入三瓣钢楔块合成的内孔中,然后将FRP杆体连同钢楔块插入到钢套筒内孔;(3)使用压力机以5 mm/min的速率将钢楔块压进钢套筒内部,直至压力值达到1.2倍的单筋拉伸荷载.至此,便完成杆体的锚固.

该锚固系统安装方便,易于拆卸,可从复使用,便于工业化的生产与应用.锚固系统内部传力明确,钢楔块与杆体之间的摩擦力沿着锚具长度方向均匀分布.此外,该锚固系统可在铝套袖与杆体之间施加一定的环向预压应力,可满足不同强度等级杆体的拉伸测试.

为了获得两种混杂杆体的层间剪切性能,采用短梁剪切测试进行表征.本文所研究的混杂杆体直径(D)为7 mm与22 mm.根据规范ASTM D4475-02[19],混杂杆体的短梁剪切试样长度为6D,测试跨度为5D,如图3所示.采用上海衡翼精密仪器有限公司生产的万能试验机(DHY-10080)进行短梁剪切测试,采用位移控制,加载速度设置为1.3 mm/min,直到杆体发生层间剪切破坏,停止实验.每种混杂杆体共测试5个试样,短梁剪切强度按下式计算.

τ=(8P)/(3πD2) (1)

式中:P为试验过程的最大荷载,N; D为杆体直径,mm; τ为短梁剪切强度,MPa.

采用挤压-摩擦型锚固系统对混杂杆体进行锚固,拉伸测试所用的混杂杆体直径为7 mm与22 mm.参考相应测试规范ASTM D7205/D7205M-06[20],将该杆切成680 mm长,中间自由长度为380 mm,两端锚固长度为150 mm.采用上海衡翼精密仪器有限公司生产的万能试验机(DHY-10080)进行拉伸测试,采用位移控制,加载速度设置为2 mm/min.直到混杂杆体发生爆裂破坏,停止加载.混杂杆体拉伸测试如图4所示,其中LVD监测杆体应变变化,结合拉力机力值数据与LVDT应变数据获得杆体拉伸应力-应变曲线.重复测试5个试样以获得平均值作为拉伸强度.

对于混杂杆体的湿热耐久性测试,采用恒温水槽进行浸泡,其中,进行湿热耐久性测试的混杂杆体直径选用22 mm.溶液采用蒸馏水,浸泡温度为40 ℃、60 ℃和80 ℃.为了加速混杂杆体的湿热老化速度,采用精密切割仪将混杂杆体沿长度方向切割成5 mm的圆片,作为水吸收试样.在进行耐久性测试之前,所有试样均放置在60 ℃进行为期7 d的烘干,用来除去混杂杆体原始的水分,同时也使得杆体内部环氧树脂得到充分固化,避免环氧树脂在浸泡过程中发生后固化.水吸收试样定期地从水槽中取出,并用纸巾擦干杆体表面的分水,试样的重量用精度为0.1 mg的电子天平进行称量,称量结束后立即将试样放还至水槽内.每种浸泡温度下的试样重复五次称量,取其平均值作为试样的水吸收值.试样的水吸收百分比值按下公式进行计算.

Mt=(Wt-W0)/(W0)×100(2)

式中:t为浸泡时间,s1/2; Mt为t时刻试样重量增加百分比,%; W0为试样初始重量,g; Wt为t时刻的试样重量,g.

为了获得混杂杆体中纤维/树脂界面性能的长期演化规律,采用面内剪切测试进行纤维/树脂界面强度的表征.由图1可以看出,UDH杆拥有一个分散的碳-玻璃纤维/树脂界面.相比而言,GCH杆存在一个GFRP皮/CFRP芯界面.为了获得上述纤维/树脂界面的粘结性能,设计出一套面内剪切装置.该装置包含压杆,固定顶盖和底座,如图5所示.所用压杆直径为12 mm,用于测试获得上述两种纤维/树脂界面的剪切强度.面内剪切测试试样与水吸收试样相同,均为5 mm厚的圆形薄片.试样在浸泡30 d、60 d与120 d后,从水槽中取出用于面内剪切测试.试样的厚度采用精度为0.001 mm的游标卡尺进行测量,采用上海衡翼精密仪器有限公司生产的万能试验机(DHY-10080)进行面内剪切测试,采用位移控制,加载速度设置为1 mm/min.每种环境下试样重复测试5次获得平均值作为面内剪切强度.

为了进一步研究不同纤维混杂模式对杆体疲劳性能的影响规律,本文参考前期研究结果[19-20],对UDH杆与GCH杆的疲劳寿命进行了对比分析,揭示了纤维混杂模式对杆体疲劳寿命的影响.根据前期研究可知,碳-玻璃混杂杆体的拉-拉疲劳测试依据ASTM D3479/D3479M-19[23]标准进行.选用100 t电液式脉动疲劳试验机进行杆体疲劳测试,应力比和疲劳频率分别设置为0.4和2 Hz.当杆体发生破坏或超过200万次的疲劳循环时,结束疲劳加载.杆体疲劳测试如图6所示.

为了充分验证挤压-摩擦型锚固系统的可靠性,选用拉伸强度较高的CFRP杆体进行拉伸测试.CFRP杆体拉伸荷载-位移曲线如图7所示.

由图可知,直径为7 mm与10 mm的CFRP杆体的荷载-位移曲线均呈线性增长,这说明挤压-摩擦型锚具内部受力均匀,CFRP杆体与钢楔块之间无滑移.对于直径为7 mm的CFRP杆体,其最大拉伸荷载达到75 kN,拉伸强度为1 950 MPa.相较而言,直径为10 mm的CFRP杆体的最大拉伸荷载达到150 kN,拉伸强度为1 912 MPa.上述两种直径杆体的拉伸强度无明显差异,这说明挤压-摩擦型锚固系统力学性能比较稳定,可适用于不同直径杆体的拉伸测试.此外,CFRP杆体的拉伸破坏模式为爆裂破坏,如图8所示.CFRP杆体的破坏发生在自由段,没有发生杆体在锚具端部被剪断的现象,这说明在钢套筒与钢楔块之间设置0.1°锥度差可有效减缓杆体在锚具端部的应力集中.总之,该挤压-摩擦型锚具与粘结型锚具相比,具有内部应力分布均匀、锚固效率高、安装便捷、可重复使用等优点.

为了研究不同纤维混杂模式与直径对短梁剪切性能的影响规律,结合前期对22 mm杆体剪切性能的研究结果[21],两种直径混杂杆体的短梁剪切荷载-位移曲线如图9所示.混杂杆体的荷载-位移曲线呈线性增长,当剪切荷载达到最大值时,杆体发生突然的脆性失效,所有混杂杆体均出现了杆体中性轴处的剪切破坏.此外,从图中还可以发现UDH杆承受的短梁剪切荷载大于GCH杆,这主要是因为GCH杆有两个独立的CFRP芯层与GFRP皮层.在生产过程中,GCH杆体的皮/芯界面会存在一些原始缺陷(孔隙、残余应力),此外,由于GFRP皮层与CFRP芯层有不同的力学性能,施加荷载后在皮/芯界面处产生应力集中.相比之下,UDH杆中的碳纤维束随机地分散到玻璃纤维中,不存在皮/芯界面薄弱层,因此获得了较高的短梁剪切荷载.由此可见,随机地纤维束混杂可以避免杆体内部出现薄弱界面,提升杆体短梁剪切性能.

为了进一步分析不同杆体直径对短梁剪切性能的影响,采用公式(1)计算出两种直径杆体的短梁剪切强度如图 10所示.由图可知,7 mm的UDH杆与GCH杆的短梁剪切强度分别为78.53 MPa与68.34 MPa,而22 mm的UDH杆与GCH杆的短梁剪切强度分别为60.85 MPa与55.65 MPa.7 mm UDH杆与GCH杆的剪切强度相较于22 mm杆体分别提升了29%与23%,可以看出直径对杆体短梁剪切性能影响是显著的.

为了进一步获得不同混杂模式与杆体直径对拉伸性能的影响,通过拉伸测试获得混杂杆体的应力-应变曲线如图 11所示.由图可知,直径22 mm的混杂杆体仅有一个弹性阶段,当拉伸荷载达到最大值时,杆体发生突然的脆性破坏.相比之下,7 mm的混杂杆体呈现三阶段的应力-应变响应,第一阶段为弹性阶段,应力-应变曲线呈线性增长.第二阶段为假延性阶段,在此阶段应力水平基本不变,应变在增加.第三阶段为杆体失效阶段,应力-应变曲线快速下降直至杆体拉伸失效.通过拉伸应力-应变响应可以看出,杆体直径对拉伸性能的影响是显著的.随着外部荷载的增加,混杂杆体内部碳纤维会首先达到断裂应变而发生断裂,大直径杆体碳纤维所承担的荷载无法均匀的转移到玻璃纤维,会在断裂处产生应力集中而导致杆体发生脆性的断裂失效.对于直径22 mm的混杂杆体,UDH杆GCH杆的应力-应变曲线无明显差异,在杆体内部的碳纤维断裂以后,两种混杂杆体均发生了过早的脆性断裂.对于直径7 mm的混杂杆体,UDH杆与GCH杆在第一阶段的应力-应变响应无明显差异.对于第二阶段,从应力-应变曲线所记录的数据点可知,UDH杆的假延性拥有较长的持续时间.相比之下,GCH杆在第一段结束后很快便进入第二阶段,这使得GCH在实际结构应用过程中,其破坏失效时无法给人足够的安全预告时间.综上可以,纤维混杂模式和杆体直径对拉伸应力-应变响应有着显著的影响.受尺寸效应的影响,通过纤维混杂无法实现大直径杆体延性的提升.相较而言,小直径杆体可以充分发挥纤维混杂效应,实现杆体的延性破坏.另外通过碳纤维束的随机混杂,可以有效提升杆体延性阶段的持续时间,为结构失效提供更长的安全预告.

通过图 11中应力-应变曲线的斜率可以得知,所有混杂杆体的拉伸模量无明显差异,这主要是因为杆体拉伸模量与纤维体积分数和碳/玻璃纤维比例有关.进一步地,通过图中应力-应变曲线计算获得混杂杆体的拉伸强度与断裂伸长率如图 12所示.由图可知,直径7 mm的UDH杆与GCH杆的拉伸强度分别为1 628.76 MPa与1 705.81 MPa,直径22 mm的UDH杆与GCH杆的拉伸强度分别为1 226.90 MPa与1 156.93 MPa.此外,直径7 mm的UDH杆与GCH杆的断裂伸长率分别为1.55%与1.67%,直径22 mm的UDH杆与GCH杆的断裂伸长率分别为1.28%与1.25%.由上述数据可以看出,小直径混杂杆体拥有更优异的拉伸性能.混杂杆体直径从22 mm降低至7 mm,UDH杆体拉伸强度与断裂伸长率分别提升33%与21%,GCH杆体拉伸强度与断裂伸长率分别提升47%与34%.

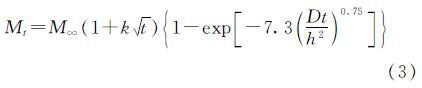

基于前期研究获得的混杂杆体水吸收数据[22],获得两种混杂杆体的水吸收曲线如图 13所示.两种混杂杆体的水吸收曲线均呈现两阶段的扩散响应,第一阶段是由浓度控制的Fick's扩散响应,第二阶段是由树脂松弛与界面脱粘控制的长期退化响应[23].在40 ℃与60 ℃浸泡温度下,UDH杆与GCH杆的水吸收与扩散行为无明显差异.相反地,两种混杂杆体在80 ℃浸泡温度下的水吸收与扩散行为差异显著,在第二阶段UDH杆拥有更高的斜率与水吸收含量.这主要是因为UDH杆存在分散的碳-玻璃纤维/树脂界面,碳纤维/树脂与玻璃纤维/树脂两者之间有不同的湿热膨胀系数,高温浸泡(80 ℃)造成UDH杆在整个横截面上纤维/树脂界面的退化,为水分子的侵入提供了更多的空间.基于上述混杂杆体水吸收行为的分析,采用Bao和Yee等人提出的两阶段扩散模型对上述水吸收数据进行拟合,拟合公式如下:

式中:t为浸泡时间,s0.5; Mt为t时刻试样水百分,%; M∞为试样在第一阶段平衡吸水率,%; D为扩散系数,×10-6 mm2/s; k为树脂结构松弛常数,10-4 mm/s0.5; h为试样的厚度,mm.

由图 13可以看出,公式(3)的两阶段模型可以很好地去拟合混杂杆体的水吸收数据,相关的拟合参数(D, k, M∞)与最大的吸水率Mmax列于表2中.值得注意的是扩散系数D和平衡吸水率M∞与第一阶段的水吸收有关,松弛常数k与第二阶段的水吸收有关.从表中数据可以看出,纤维混杂模式对M∞的影响是可以忽略不计的.此外,UDH杆的松弛系数相较于GCH杆更易受浸泡温度的影响,80 ℃高温浸泡导致UDH杆拥有较高的松弛常数k.这主要是因为碳-玻璃纤维/树脂界面在高温浸泡下退化显著,为第二阶段的水吸收带来了严重的松弛现象.综上可以,不同的纤维混杂模式对高温(80 ℃)浸泡下的水吸收行为有显著影响.

通过面内剪切测试,结合前期对混杂杆体界面性能的研究结果[22],获得两种混杂杆体面内剪切强度随浸泡时间的退化曲线如图 14所示.

由图中曲线的斜率可知,混杂杆体的面内剪切强度在初始浸泡的第一个月内退化显著,随后退化速率减小.这主要是因为在初始浸泡的一个月内,水分子的侵入打破了原始树脂链间、树脂链与纤维间的范德华力与氢键,导致树脂发生了严重的塑化反应与界面脱粘.此外,浸泡温度会加速树脂塑化与界面脱粘,在同一浸泡时间下,面内剪切强度退化百分比随着浸泡温度的增加而升高.对比两种混杂杆体的退化数据可知,在40 ℃与60 ℃浸泡温度下,两种混杂杆体面内剪切强度的退化百分比无明显差异.相反地,在80 ℃浸泡温度下,UDH杆的面内剪切强度退化百分比远高于GCH杆.由图 13已知,UDH 杆的水吸收率远高于GCH杆,两种混杂杆体的强度退化与水吸收结果相吻合,说明杆体吸水量越多,由塑化和界面脱粘所导致的面内剪切强度退化率越高.综上可知,不同纤维混杂模式会影响杆体水吸收,水分子的侵入导致杆体发生不同程度的塑化作用与界面脱粘,进而导致不同程度的面内剪切强度退化.

根据前期的研究结果[19-20],混杂杆体的S-N曲线绘制于图 15.由图可知,在相同的应力比下,随着应力水平的升高,两种混杂杆体的疲劳寿命显著降低,这是因为较高的应力水平加速杆体疲劳损伤的萌生和扩展.对于UDH杆,在应力水平为0.33时,疲劳循环次数超过200万次.相比之下,当施加在GCH体的应力水平降低到0.25时,可以实现上述超过200万次疲劳循环的目标UDH杆的疲劳极限比GCH杆提高了40%,这说UDH杆比GCH杆拥有更好的抗疲劳性能.在应力水平为0.42时,UDH杆的疲劳寿命是GCH杆的5.7倍.此外,GCH杆的疲劳失效模式为皮/芯界面脱粘,UDH杆的疲劳失效模式为均匀的碳玻璃纤维/树脂界面的劈裂破坏.综上所述,纤维混杂方式对杆体疲劳寿命与破坏模式的影响是显著的,通过碳纤维束的随机混杂,可以有效地提高UDH杆的抗疲劳性能.可以看出,UDH杆疲劳寿命优于GCH杆,主要原因是UDH杆的碳纤维束随机地分散在玻璃纤维中,避免了在疲劳过程中GCH杆皮/芯界面脱粘而导致杆体发生过早的疲劳失效.UDH杆中碳纤维与玻璃纤维束可以协调抵抗疲劳荷载,充分发挥了碳纤维的耐疲劳性能,有效地延缓了杆体疲劳失效的到来,大幅提升了UDH杆的疲劳寿命.

为促进碳-玻璃纤维混杂增强环氧树脂基复合材料拉挤杆在工程结构中的应用,本文发明了一套高效挤压-摩擦型锚固系统,研究了纤维混杂模式(随机混杂与包覆混杂)对混杂杆体静力、湿热老化与疲劳性能的影响规律,具体结果如下:

(1)发明的新型楔形-摩擦型锚固系统避免锚固区内的应力集中,锚固效率高达100%.杆体与楔块之间无滑移,杆体失效模式为自由段的爆裂破坏,可有效解决复合材料杆体的锚固难题;

(2)相较于皮-芯包覆混杂,碳纤维束的随机混杂可以有效提升混杂杆体短梁剪切性能.受尺寸效应的影响,大直径(22 mm)混杂杆体无法实现拉伸正混杂效应.相反地,通过碳纤维束随机混杂的小直径(7 mm)杆体,具有显著的拉伸断裂延性;

(3)混杂杆体水吸收行为符合两阶段模型.80 ℃高温浸泡下,随机混杂杆体具有较高的水吸收,水分子的侵入导致树脂的塑化与界面脱粘,进而引起随机混杂杆体显著的界面性能退化;

(4)通过碳纤维束的均匀混杂,实现了疲劳性能的正混杂效应,随机混杂杆获得了较高的疲劳寿命.这是由于随机混杂杆中碳纤维与玻璃纤维束可以协调抵抗疲劳荷载,充分发挥了碳纤维的耐疲劳性能,有效地延缓了杆体疲劳失效的到来;

(5)随机混杂杆体具有优异的拉伸与疲劳性能,适用于经常承受交变荷载的工程结构,如桥梁拉索、混凝土预应力筋等.相比之下,包覆杆体具有较好的长期耐久性能,适用于服役环境较恶劣的工程结构,如海洋平台系泊系统、海洋混凝土结构等.